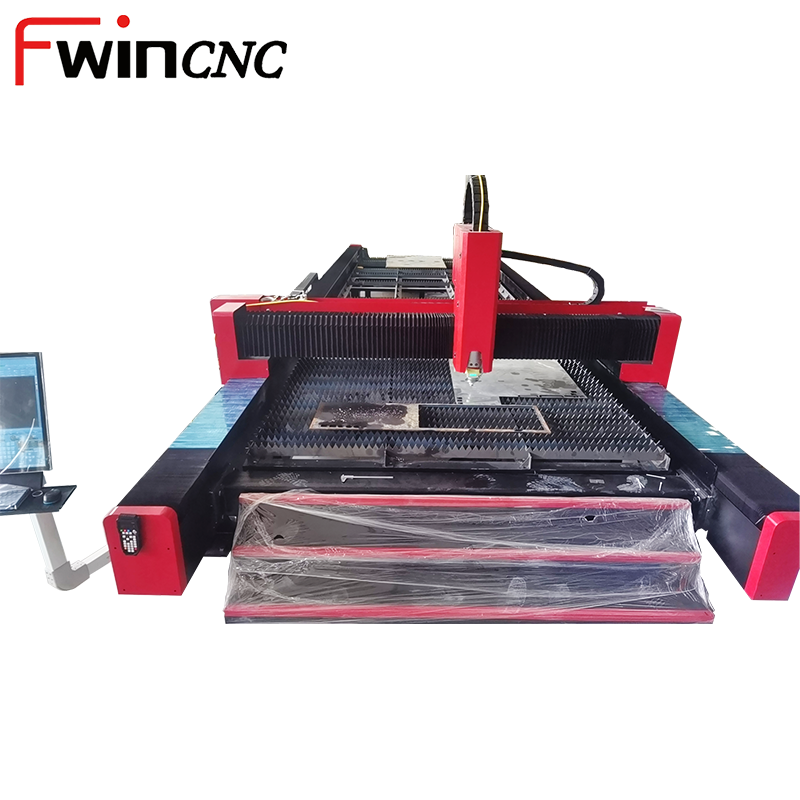

Dish Head Dome Plasma Pressure Vessel Bevel Cutting Machine

Plasma bevel dish head cutting machine is a CNC plasma cutting equipment specially used for processing end heads and completing bevels at the same time. It is mainly used in petrochemical industry, pressure vessels, boilers, pipelines and other industries. It is used to cut round, oval, disc and other seals, and accurately process the bevel angle required for welding to ensure the quality of subsequent welding.

1. Highly efficient and precise head processing capability

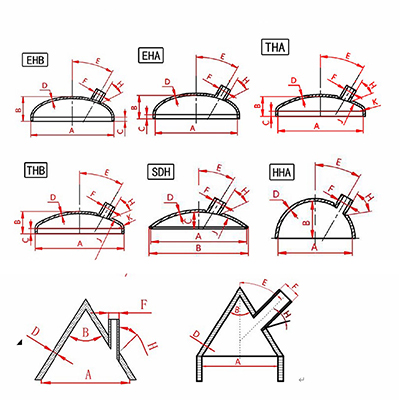

It is specifically designed for dish heads: it can cut complex curved end caps such as Ellipsoidal, Torispherical, Hemispherical, Conical, Toriconical, etc., meeting the needs of the petrochemical and pressure vessel industries.

2. Integrated beveling function to improve welding quality

Intelligent bevel cutting and One-time cutting forming: supports various bevel angles such as V-type, X-type, K-type (e.g., 30°, 45°, 60°), meeting different welding process requirements.

3. Automation and intelligent operation

CNC programming: supports CAD/CAM drawing import, automatically generating cutting paths, reducing manual intervention.

Automatic height adjustment system: real-time adjustment of cutting torch height, adapts to curved surface cutting, avoiding collisions or arc breaks.

4. Strong adaptability, covering various materials and thicknesses

Wide range of materials: can cut metals such as carbon steel, stainless steel, alloy steel, aluminum, etc., suitable for different industrial scenarios.

Efficient cutting of medium and thick plates: Plasma power covers 100A~400A, can process thicknesses of 5~100mm (depending on power), and speeds are 3~5 times faster than flame cutting.

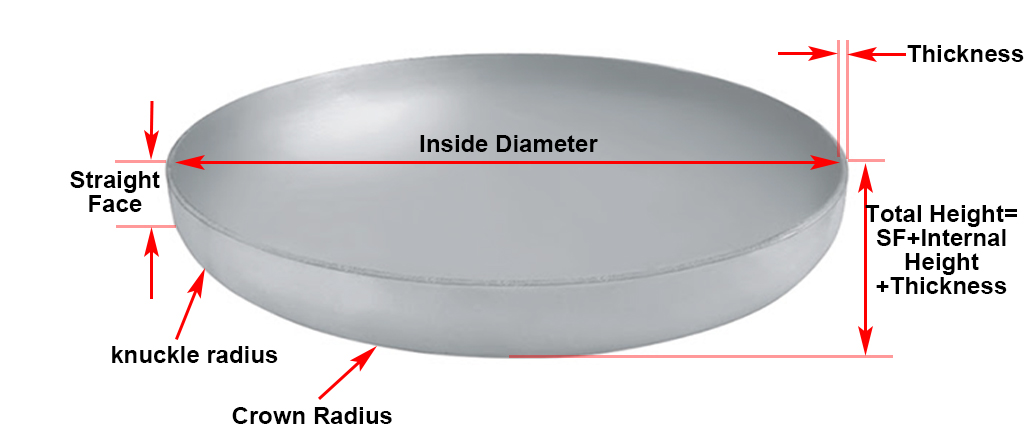

What is a head?

Head is a curved structural member used to close off the end of a pipe, vessel or equipment, usually in the shape of a circle, oval, disk, cone or hemisphere. It is an important part of pressure vessels, tanks, piping systems and other equipments, playing the roles of sealing, pressure bearing and structural support.

| Effective length of work area | 3,000 to 30,000 mm |

| Effective width of work area | 1,500 to 8,000 mm |

| Possible cutting processes | plasma, oxyfuel |

| Maximum material thickness plasma | according to plasma source |

| Maximum material thickness oxyfuel | 200 mm |

| Positioning speed | up to 40,000 mm/min |

| Positioning accuracy | ≤ 0.10 mm/m |

| X, Y axis | linear guides, driven on both sides and helical toothed racks |

| Z axis | ball screw |

| Gantry type | massive steel gantry |

Plasma Vessel Head Cutting Machine Applications

Applications

(1) Pressure Vessel Industry

Boiler Head, Reactor Vessel End Cover, Tank Head

(2) Oil and Gas

Pipeline End Caps, Spherical Tank Heads, Flange Connectors

(3) Shipbuilding and Marine Engineering

Hull Curved Components, Hatch Covers, Propulsion Components

(4) New Energy Equipment

Wind Turbine Tower Heads, Hydrogen Storage Tanks, Nuclear Power Equipment

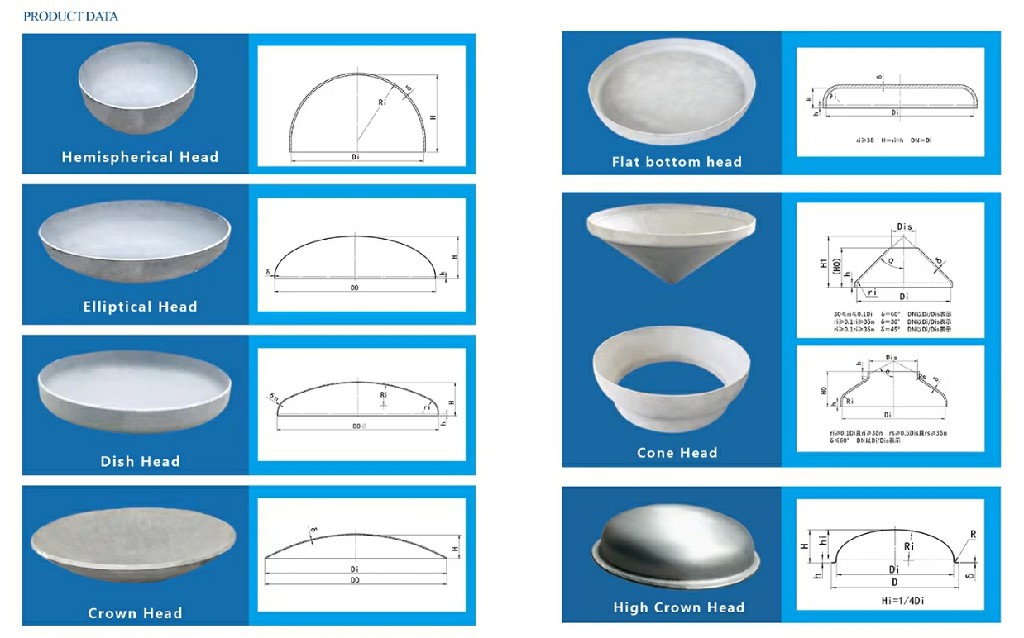

| Type | Shape Characteristics | Typical Applications |

| Elliptical Head | Semi-ellipsoidal surface, moderate

depth |

Pressure vessels, chemical reactors (most

common) |

| Hemispherical Head | Semi-spherical shape, highest

pressure resistance |

High-pressure boilers, nuclear power

equipment |

| Dished Head | Shallow curved surface with

central spherical crown and transition ring |

Low-pressure storage tanks,

food/pharmaceutical equipment |

| Conical Head | Conical or tapered structure | Pipe reducers, granular material discharge

ports |

| Flat Bottom Head | Flat plate structure (simple but

weak pressure resistance) |

Atmospheric pressure vessels, manhole

covers |

plasma head cutting VS traditional processing methods

| Comparison Item | Traditional Method (Manual +

Milling) |

CNC Plasma Head Cutting Machine |

| Processing Accuracy | ±2mm | ±0.5mm |

| Bevel Quality | Requires secondary processing,

inconsistent |

One-step forming, uniform and precise |

| Production Efficiency | 8-12 hours/piece | 1-2 hours/piece |

| Labor Dependency | Highly skilled welders/millers

required |

Automated operation, low dependency |

| Material Utilization Rate | 60%-75% | 85%-92% |

Get Free Quote of Plasma Head End Cutter

✅ Industry Verification: Providing CNC equipment for 500+ enterprises in 20+ countries worldwide

✅ Turnkey Project: Provides a complete solution from equipment selection to process verification

✅ Service and Support: 2-year warranty on key components, on-site operation and programming training

Related News

To ensure welding quality, the workpiece can be prepared at the weld joint using gas cutting or mechanical cutting before […]

Plasma cutting and Laser cutting Plasma cutting and laser cutting are both popular methods for cutting materials,they are both highly […]

5-axis gantry CNC plasma round tubebeveling cutting machine 2 sets of 5-axis gantry CNC plasma round tube beveling cutting […]

3 sets of 5-axis CNC gantry bevel plasma cutting machines were shipped to Vietnam. In the metal cutting industry, we […]