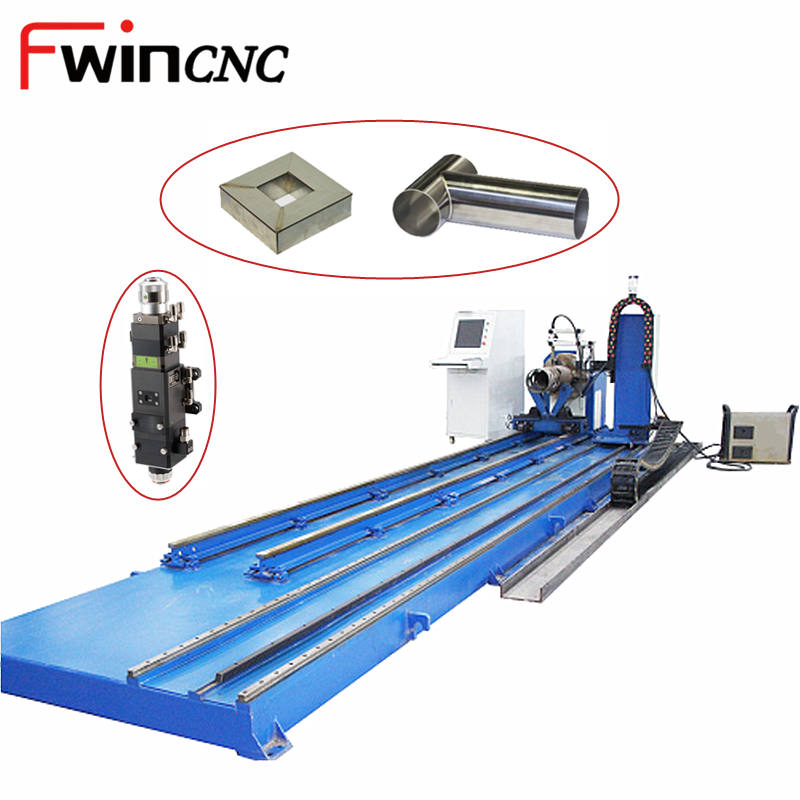

Why Choose Light Square Round Tube Pipe Laser Cutting Machine?

The Light Square Round Tube Pipe Laser Cutting Machine fully considers the impact of pipe wall thickness on the intersecting profile. The programming algorithm employed can effectively solve data processing issues at the transition areas between the inner and outer walls, ensuring proper alignment of the intersecting joints.

The software covers 7 major categories and 21 different types of common intersecting node configurations in engineering, and these nodes can be combined in any arbitrary way. This makes the software suitable for industries such as oil and gas pipelines, simple pipe trusses, and pressure vessels.

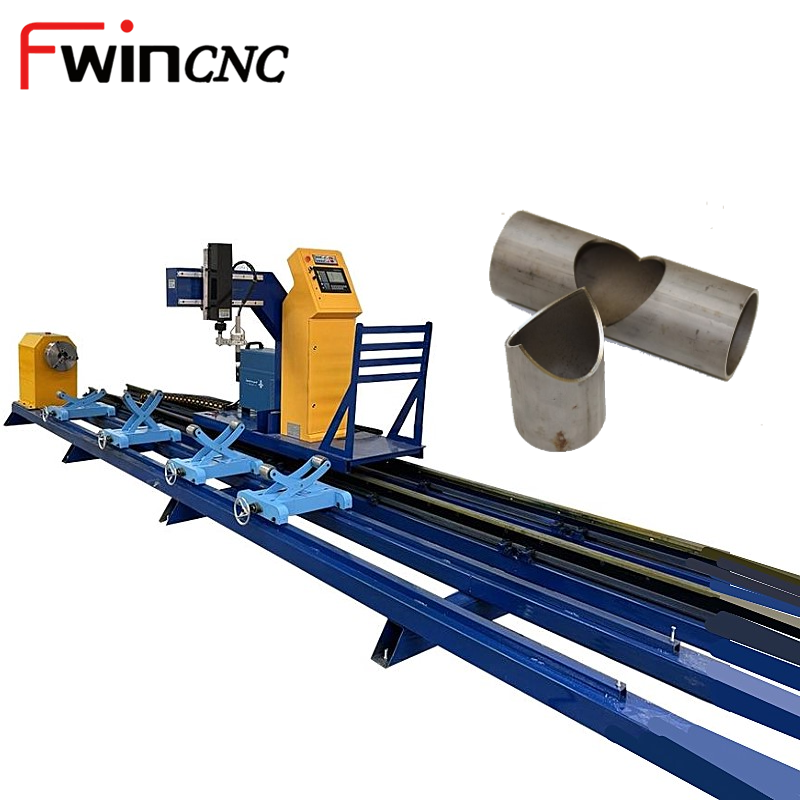

The forms of cutting pipe penetration holes or branch pipe penetration nodes are as follows: