To ensure welding quality, the workpiece can be prepared at the weld joint using gas cutting or mechanical cutting before welding. The edge is typically beveled (sometimes curved). For example, when butt-welding two 10mm-thick steel plates for a strong joint, the edges are machined with a bevel, known as a groove. Depending on material thickness and welding quality requirements, joint configurations and groove shapes vary. Common groove types include K-type, V-type, I-type, U-type, and X-type.

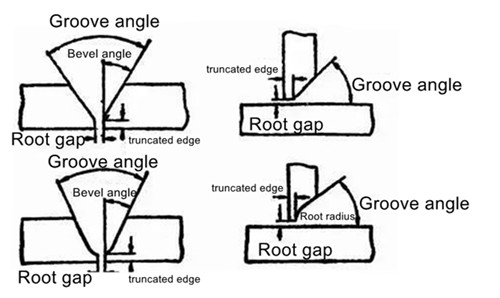

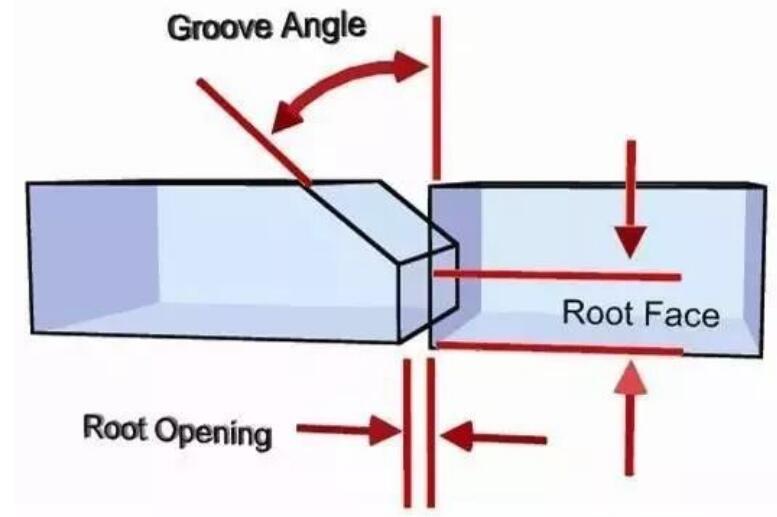

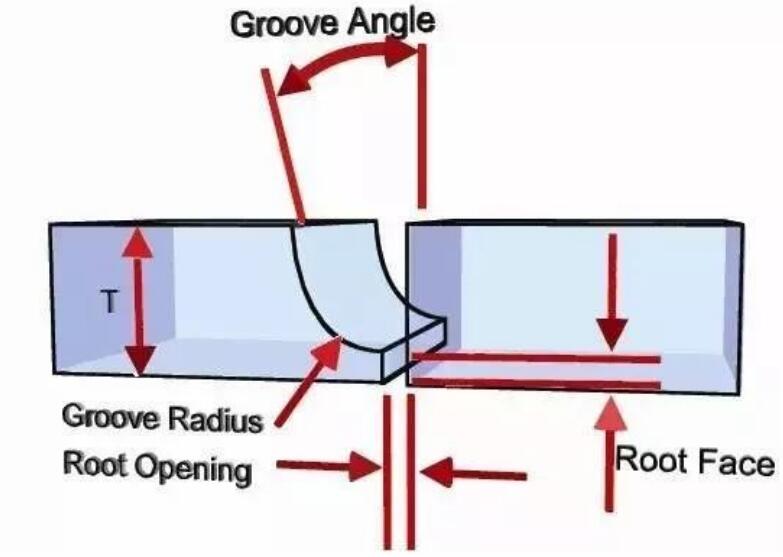

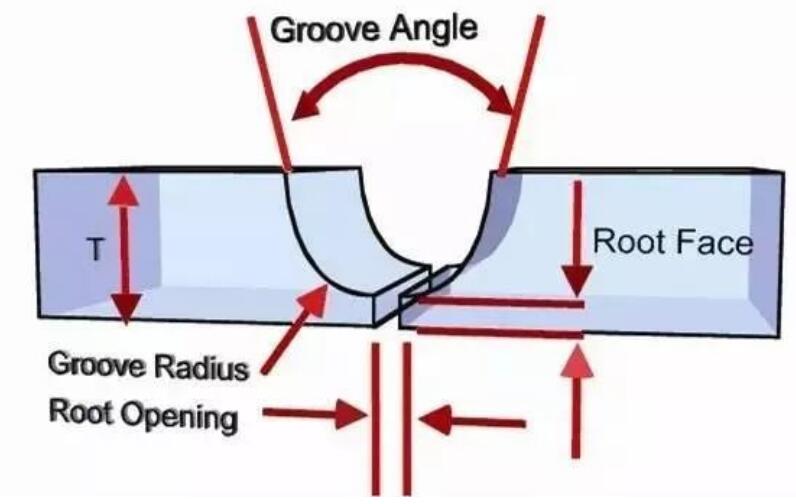

Geometric Dimensions of a Groove

- Groove Face

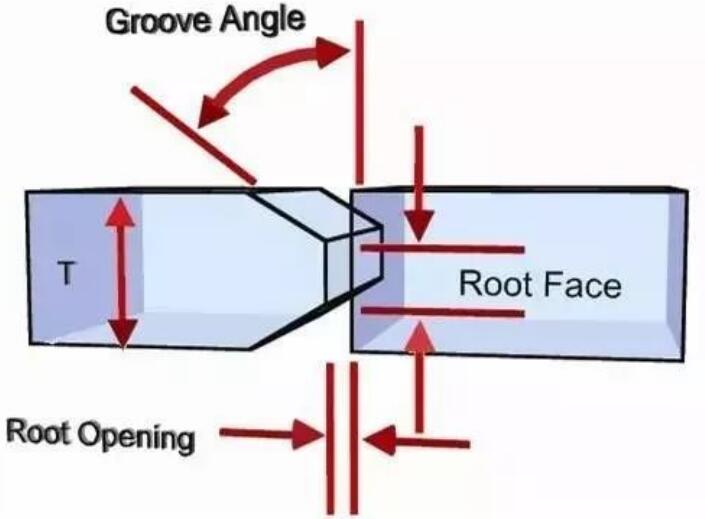

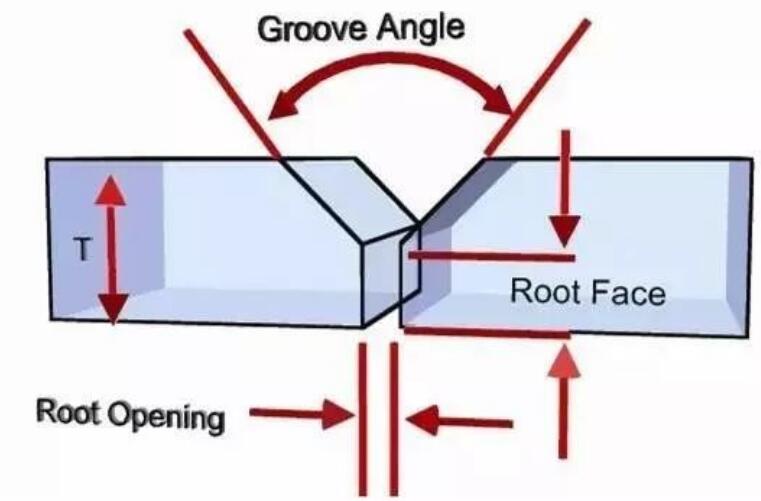

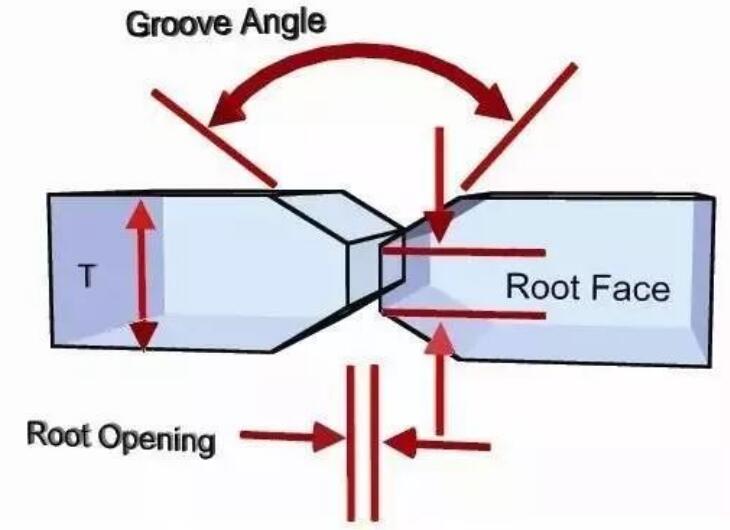

The beveled surface of the workpiece to be welded is called the groove face. - Groove Face Angle & Groove Angle

The angle between the groove face and the workpiece end face is the groove face angle, while the angle between two groove faces is the groove angle. - Root Gap (Root Opening)

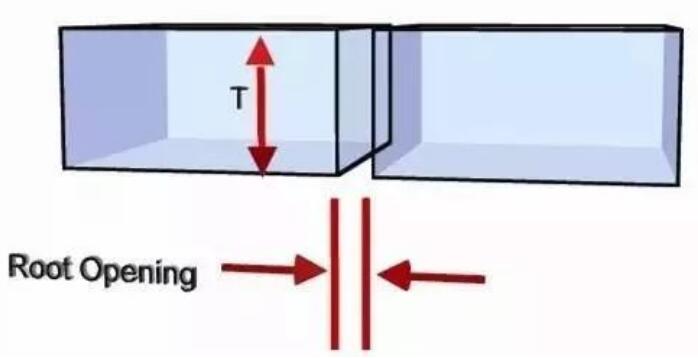

The intentional gap left between the joint roots before welding is called the root gap. It ensures full penetration during root pass welding. Also referred to as assembly gap. - Root Face (Land)

The flat, un-beveled portion at the base of the groove is called the root face. Its purpose is to prevent burn-through. - Root Radius

The root radius is the curvature at the bottom of J-type and U-type grooves. It enlarges the space at the root to improve penetration.

Common Groove Types

Purpose of Grooves

The primary function of a groove is to ensure full root penetration, allowing the welding heat source to reach the joint’s base and guarantee weld integrity. Additionally, grooves help control the weld metal-to-base metal ratio.