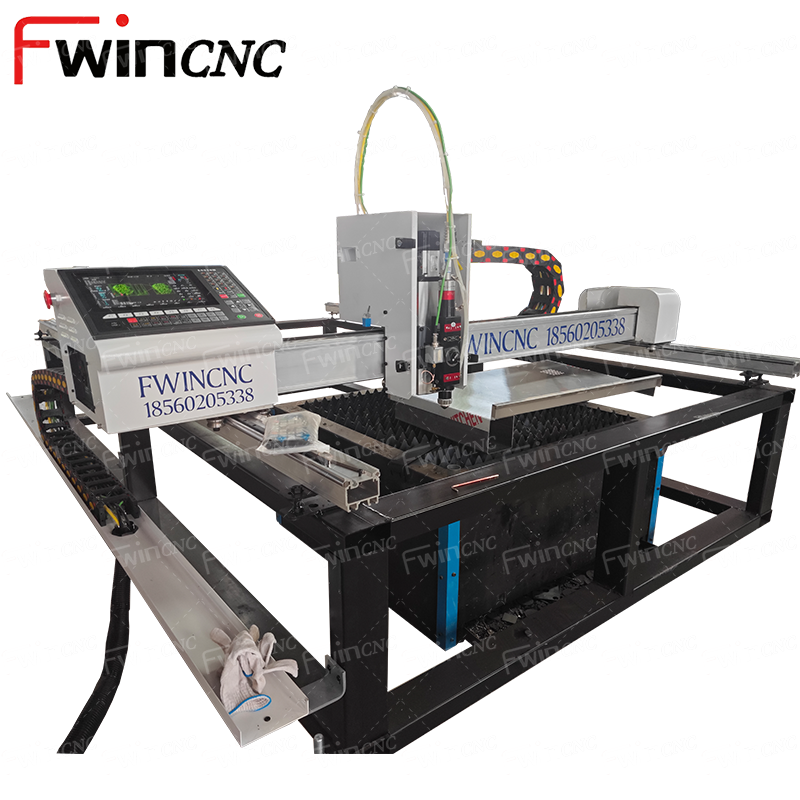

CNC Gantry Plasma Cutting Machine

High-precision gantry CNC plasma cutting machine for metal fabrication, offering durable structure, large format cutting, and reliable industrial performance.

-

Heavy-Duty Gantry Structure – Rigid welded frame ensures stability for long-term industrial use.

-

Large Format Cutting – Supports wide cutting ranges for sheet, plate, and structural steel.

-

High-Precision CNC Control – Delivers ±0.2mm accuracy with smooth motion and clean edges.

-

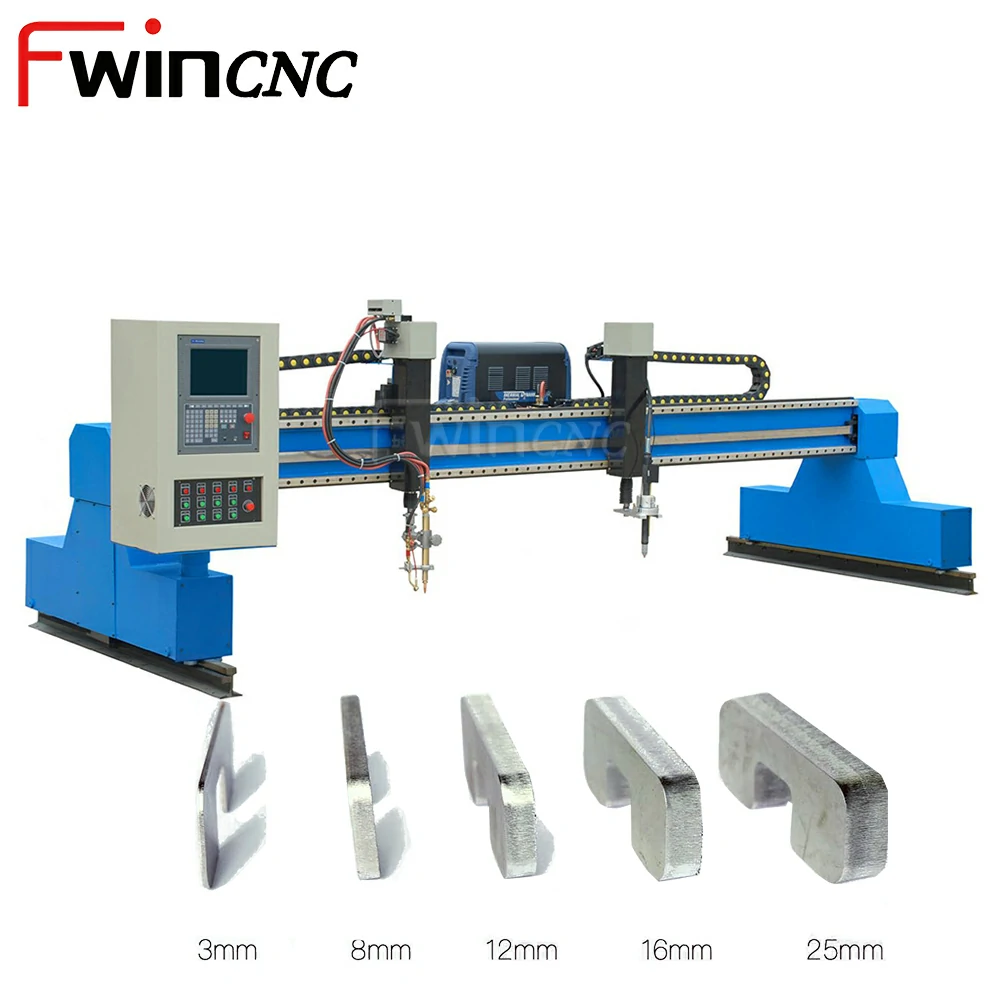

Versatile Cutting Options – Compatible with plasma or flame cutting for diverse materials and thicknesses.

-

Cost-Effective for B2B Users – Balances reliable performance with reduced operating costs.

Gantry Plasma Cutter Description

The gantry CNC plasma cutting machine is designed for heavy-duty metal fabrication, providing a stable structure and precise CNC control system. Built with a rigid welded gantry frame and high-precision linear guide rails, this machine ensures long-term durability and reliable cutting accuracy.

With its large-format cutting capacity, it is ideal for processing steel plates, sheet metal, and structural profiles such as H-beams and angle irons. Whether using plasma or flame cutting, the machine delivers clean edges, smooth cuts, and consistent performance across different material thicknesses.

For industrial users seeking efficiency, this heavy-duty plasma cutter for metal fabrication reduces production costs while improving throughput. It supports diverse industries such as shipbuilding, construction, machinery manufacturing, and energy equipment, helping businesses achieve higher productivity and reliable results.

Gantry construction Robust and durable

Gantry construction Robust and durable| No. | Model 3060 | CNC plasma | |||

| 1 | X axis working area | 3m | |||

| 2 | Y Axis working area | 6m | |||

| 3 | cutting heading | 2 independent portal-bridge | |||

| 4 | Cutting Mode | Plasma torch+ flame torch | |||

| 5 | Driving motor | stepping motor and driver | |||

| 6 | cutting gas | flame: oxygen+acetylene/propanel | |||

| plasma: compressored air | |||||

| 7 | drive mode | double driver | |||

| 8 | cutting torch | automatic one Plasma torch+automatic one flame torch | |||

| 9 | Controller system | one set of FANGLING | |||

| 10 | Software | one set of Austraila FASTCAM | |||

| 11 | lifter | traveling distance1- 200mm | |||

| 12 | Plasma power | huayuan lg-200ha | |||

| 13 | file transmission | usb | |||

| 14 | comprehensive precision | ±0.5mm | |||

| 15 | software | fast CAM(support auto cad/Soliworks/caxa/types | |||

| 16 | Torch height controller | Automatic THC | |||

| 17 | input power | 1 phase AC 220V for CNC machine | |||

| 3 phrase AC 380V for plasma power | |||||

| 18 | display screen | LCD color screen with 10.4inch size | |||

| 19 | guide rail for y axis | steel rails 24kgs per meter | |||

| 20 | guild rail for x axis | Precision double-axis guide rail | |||

| 21 | we test following comprehensive precision 1000mm*1000mm speed of marking on 500mm-800mm/min |

1.Straight line :±0.2 mm 2. round tolerance:±0.5mm 3.repate postion:±0.4mm | |||

| 22 | install precision for guild rail | straight line tolerance:0.5mm/10000mm | |||

| Horizontal accuracy:±0.1mm/1000mm | |||||

| 23 | surface of cutting thickness (quality cutting condition) |

Ra≤12.5μm | |||

| 24 | Package size(L*W*H) | 4600MMX2100MMX1700MM CNC PLASMA | |||

| 1050MM*500MM*1070MM 200A PLASMA SOURCE | |||||

heavy-duty gantry plasma cutting machine Applications

The gantry CNC plasma cutting machine is widely used across multiple industries due to its ability to process thick plates, structural steel, and complex profiles. Its large-format cutting range and dual plasma/flame options make it highly versatile.

-

Shipbuilding & Offshore Engineering – Cutting large steel plates for hulls, decks, and structural components.

-

Construction & Heavy Machinery – Processing beams, columns, and thick structural parts for buildings and equipment.

-

Petrochemical & Energy – Fabricating pipelines, pressure vessels, boilers, and power plant structures.

-

Automotive & Aerospace – Producing chassis parts, frames, and high-strength components with precision.

-

Metal Fabrication & Manufacturing – Handling custom sheet metal, machinery parts, and industrial tools.

This heavy-duty gantry plasma cutting machine helps manufacturers enhance productivity, ensure consistent quality, and reduce overall cutting costs, making it a preferred choice for modern industrial production.

Inquire Now: Gantry Plasma Cutting Solutions

Looking for a reliable gantry CNC plasma cutting machine to boost your production efficiency? Our heavy-duty design ensures long-lasting stability, large-format cutting capacity, and clean, precise results across a wide range of metals.

By choosing FWINCNC, you gain cost-effective solutions, global after-sales support, and customizable options tailored to your business needs.

📩 Submit your inquiry today and let our team provide you with the best cutting solution for your industry.