Laser Power Supply Indicator Light Blinking

Quick Troubleshooting Guide for Fiber Laser Users

If your fiber laser power supply indicator light keeps blinking, don’t panic.

In most cases, this is a protective warning, not a serious laser failure.

This quick guide explains what it means and what to check, in plain language.

What Does a Blinking Indicator Light Mean?

A blinking red or alternating red-green light usually indicates that the laser power supply is not in normal working status.

Common reasons include:

-

Power signal abnormality

-

Cooling water issues

-

Incorrect internal power settings

-

Unstable input voltage

Most of the time, the laser source itself is not damaged.

Step 1: Safety Check (Do This First)

Before any inspection:

-

Turn off the main laser power

-

Shut off the cooling water

-

Wait at least 10 minutes after power-off

-

Make sure there is no residual voltage

This avoids electric shock and component damage.

Step 2: Check Cooling Water System

Cooling problems are a very common cause of alarms.

Make sure:

-

All water pipes are fully inserted and locked

-

No leaks or loose connections

-

Water flows normally after restarting

After restoring water, wait a few minutes and observe the indicator light again.

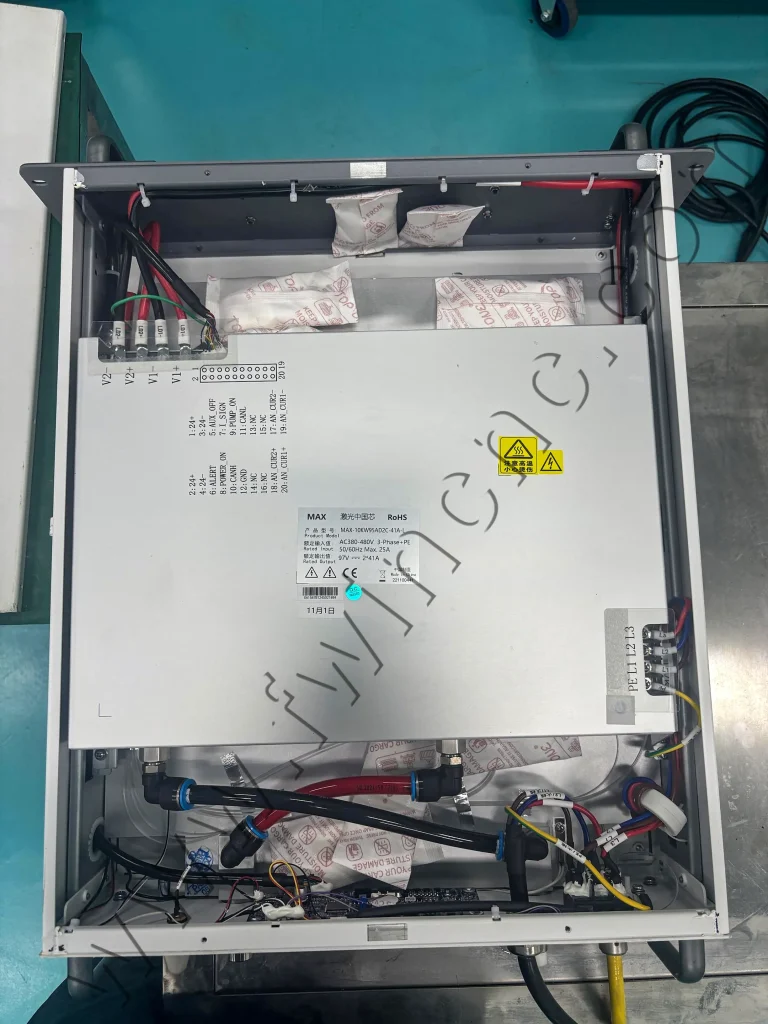

Step 3: Check Power and Signal Connections

Next, inspect the wiring:

-

Input power should be stable (usually AC 380V ±5%)

-

Power cables must be firmly connected

-

Control and signal wires should not be loose or reversed

Even a small connection issue can trigger warning lights.

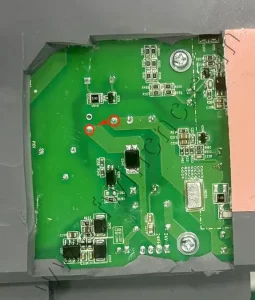

Step 4: Power Supply Adjustment (If Required)

In some cases, the power supply needs a simple internal adjustment to return to normal operation.

This may include:

-

Opening the power supply cover

-

Removing protective silicone in a specific area

-

Bridging designated solder points

This step should be handled by trained technicians only.

Step 5: Power-On and Functional Test

After everything is restored:

-

Turn on cooling water and check for leaks

-

Power on the system

-

Observe the indicator light

-

Alternating red and green usually means normal status

-

-

Run a low-power laser test (around 10%)

-

Let the machine run for 20–30 minutes to confirm stability

Final Summary

A blinking laser power supply indicator light is usually a warning, not a failure.

Most issues are related to cooling, wiring, or power settings, and can be resolved with basic checks.

If the alarm continues after inspection, professional technical support is recommended.