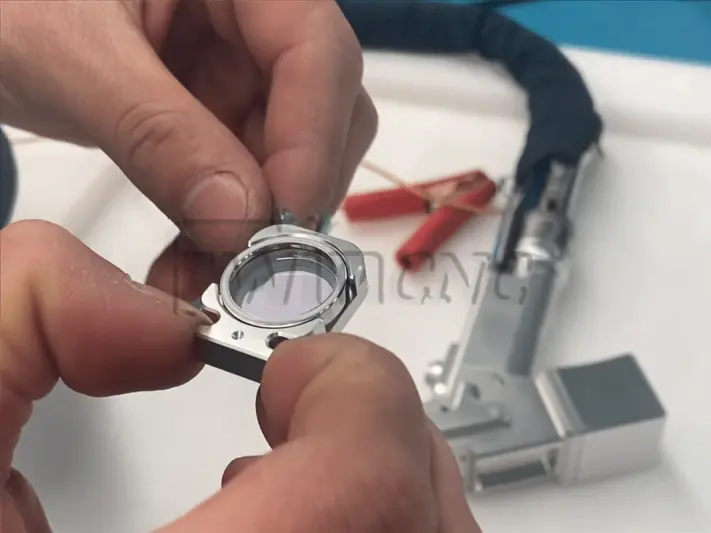

Laser welding lenses are critical components of any laser welding machine. Without proper care, lenses can suffer damage, leading to costly replacements and reduced welding performance. Understanding the common causes of lens damage and following preventive measures can significantly extend lens life.

Common Causes of Laser Welding Lens Damage

-

Improper process parameters causing spatter to hit the lens.

-

Excessive defocusing during welding, with the scale tube too close to the workpiece.

-

Exhausted shielding gas or missing a 24V DC relay, causing the solenoid valve to operate directly from the control board.

-

Using thick welding wire on thin materials, generating spatter that damages the lens.

Effective Welding Spatter Solutions and Preventive Measures

-

Consult the process library for the correct wire diameter based on material thickness. Adjust laser power swing width, swing frequency, and feed rate to minimize spatter and protect the lens.

-

Position the scale tube precisely at the focal point during welding. For zero-scale operations, ensure the QBH is securely tightened. Video tutorials can guide proper setup.

-

Maintain shielding gas pressure at around 0.3 MPa using nitrogen or argon. Install a 24V DC relay to control gas flow, connecting relay coils to 24V and the solenoid valve to normally open on the 24V power supply.

-

Avoid using coarse wire on thin sheets, as this can burn through the material and create spatter, posing a risk to the lens.

Following these laser welding tips and solutions for spatter control helps prevent lens damage, lowers maintenance costs, and improves welding efficiency. Prioritizing laser welding lens protection ensures your equipment delivers consistent, high-quality performance.