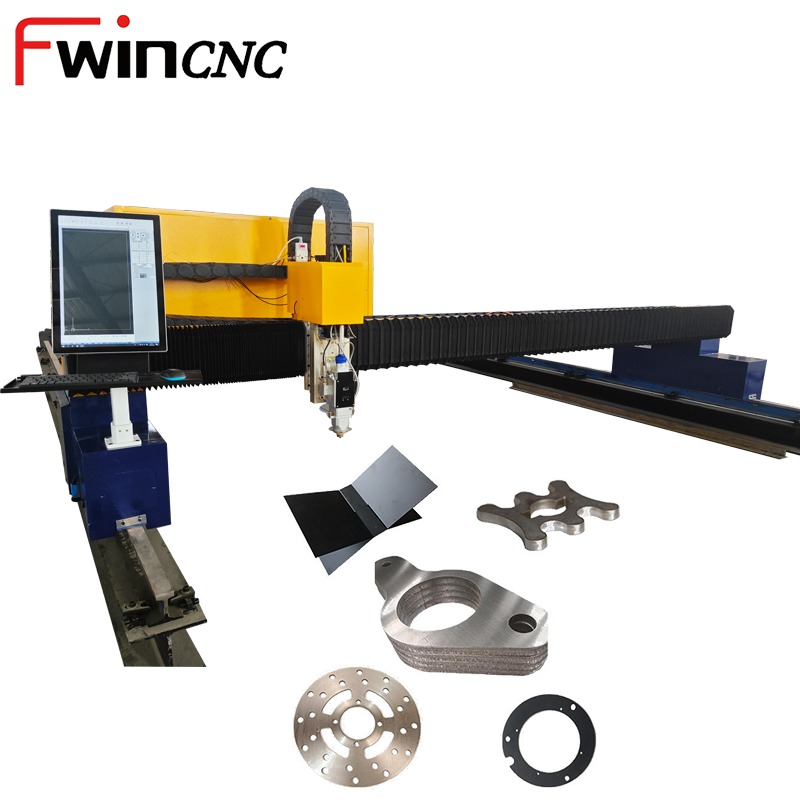

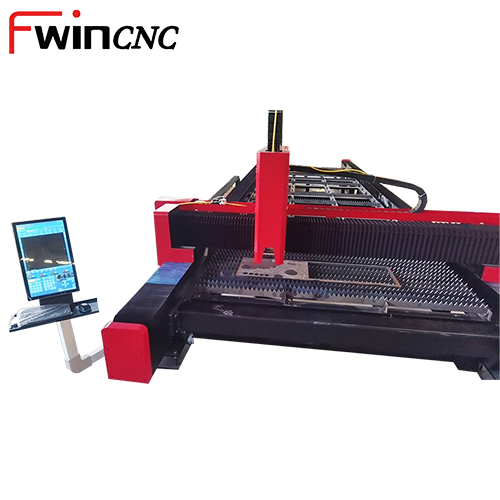

Stable Large Format Ground Rail Laser Cutting Machine

The ground rail laser cutting machine is primarily used for cutting larger area, heavier metal sheets, with a wider working range and more stable operation.

Features of ground rail laser cutting machine

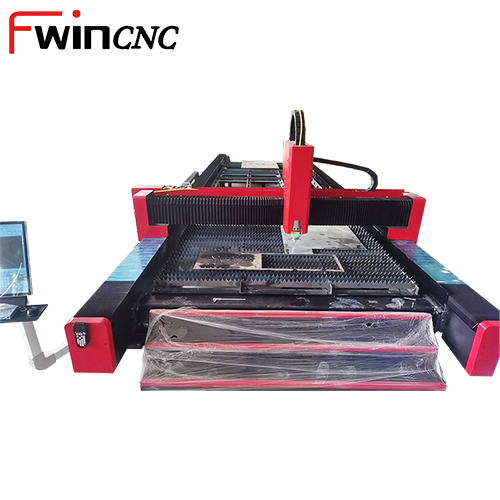

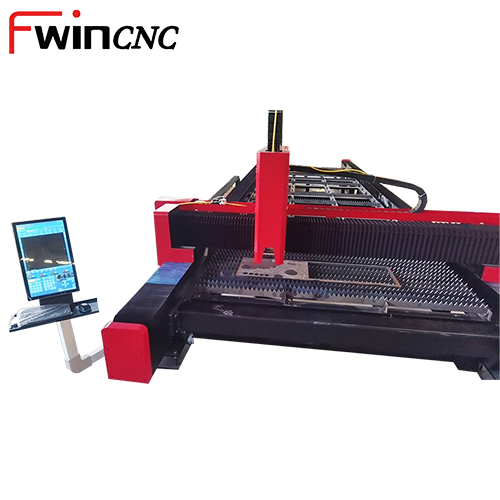

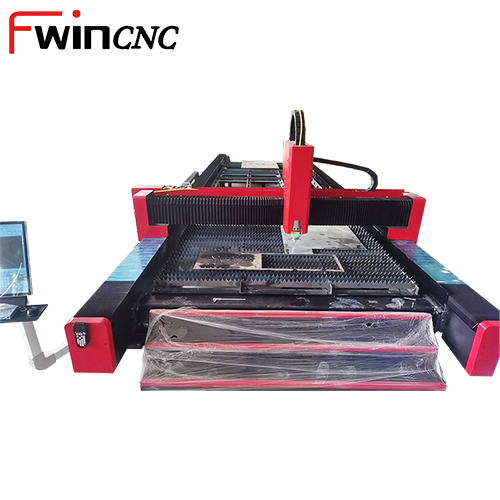

1. The ground rail laser cutting machine boasts a spacious working area, allowing for cutting of large format materials with ease.

2. With high power capabilities, this machine can efficiently cut through various materials with precision and speed.

3. It is designed with excellent thermal and gravitational isolation features, ensuring stable and accurate cutting results.

Ground Rail Laser Cutting Machine Description

| Item | Description |

| Laser source |

|

| Water chiller |

|

| Smoke exhaust and dust removal fan |

|

| Cutting head and height sensor |

|

| Motor drive |

|

| Wireless handset |

|

| Control system |

|

| Programming software |

Supports various graphic data formats such as AI, DXF, PLT, Gerber, and more,making it easy to design layouts. Ensures high precision in processing due to its excellent mechanical and electrical drive dynamic performance. Addresses the issue of focus fluctuation caused by uneven plate surfaces by implementing a z axis follow-up feature, which maintains a fixed focus. Enhances processing efficiency and control through analog graphic display and dynamic graphic tracing display, providing a more intuitive monitoring and control experience. Equipped with multiple alarm functions, including self-checking alarm and automatic protection features in the CNC system, ensuring safety and protection even in external conditions. |

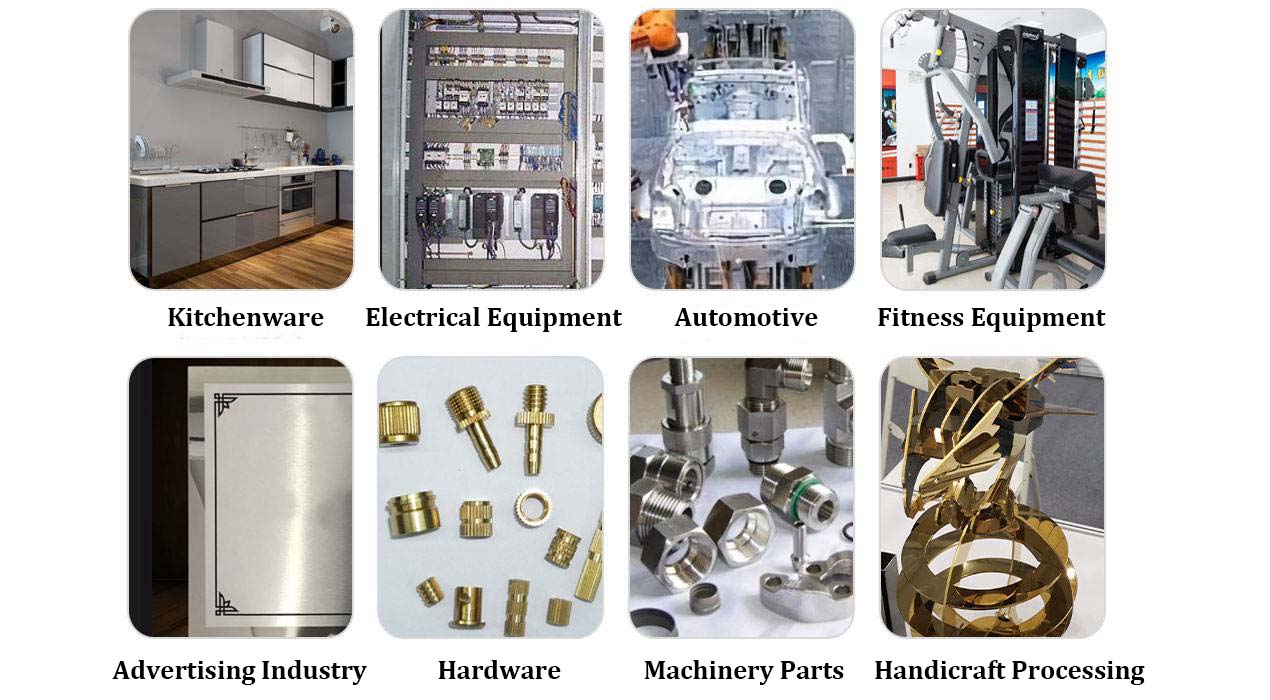

Ground Rail Laser Cutting Machine Applications

The Ground Rail Laser Cutting System offers versatile operation across a diverse range of metal materials, from stainless steel to manganese steel, galvanized sheet, and alloy plates. With broad applications spanning the automotive, kitchenware, e-bicycle, medical, sporting goods, and furniture sectors, it serves as an efficient tool for precision cutting solutions.

The traditional cutting method has some limitations

Although the cutting thickness does have some restrictions, the precision isn’t assured, and the medium-to-heavy plates may require secondary processing for optimal results.

Traditional cutting methods have specific size limits, exceeding which necessitates separate operations. They’re also unable to handle ultra-long or ultra-large format parts efficiently. Additionally, these methods produce smoke and dust, posing potential environmental hazards.

Technical advantages of ground rail laser cutting machine

Our large-scale ground rail laser cutter boasts a segmented bed with smoke exhaust devices for precise, eco-friendly, and safe operation.

Its extensive workbench customizes various sizes, accommodating extra–length and extra-wide materials, allowing comprehensive processing of ultra-long parts.

Featuring optimized configuration, robust cutting power for medium and heavy plate cuts, intelligent blanking for time and resource savings.

With its high power, high configuration, and high efficiency, it effortlessly handles long and thick plates, ensuring peak efficiency and superior cutting quality.

Get Free Quote of Ground Rail Laser Cutting Machine

FWINCNC presents the latest advancement in laser cutting machines – the ground rail model. This state-of-the-art machine guarantees heightened efficiency, safety, reliability, and environmental friendliness.

Related News

Investing in a laser cutting machine is a significant step toward enhancing your manufacturing capabilities, improving precision, and boosting productivity. […]

Laser cutting machines are a valuable asset for many industries Laser cutting machine is a valuable asset for many […]

In recent years, the advent of portable laser cutting machines has significantly transformed the landscape of precision cutting in various […]

The application of laser technology has emerged as a game-changer in the manufacturing processes of automobiles The automotive industry has […]