Scalable cutting, beveling, welding, and tube processing systems engineered for stable output, high load operation, and long-term industrial production.

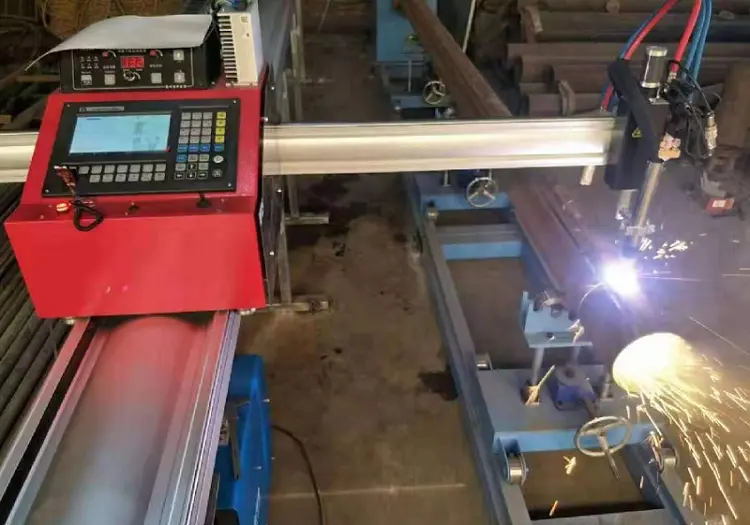

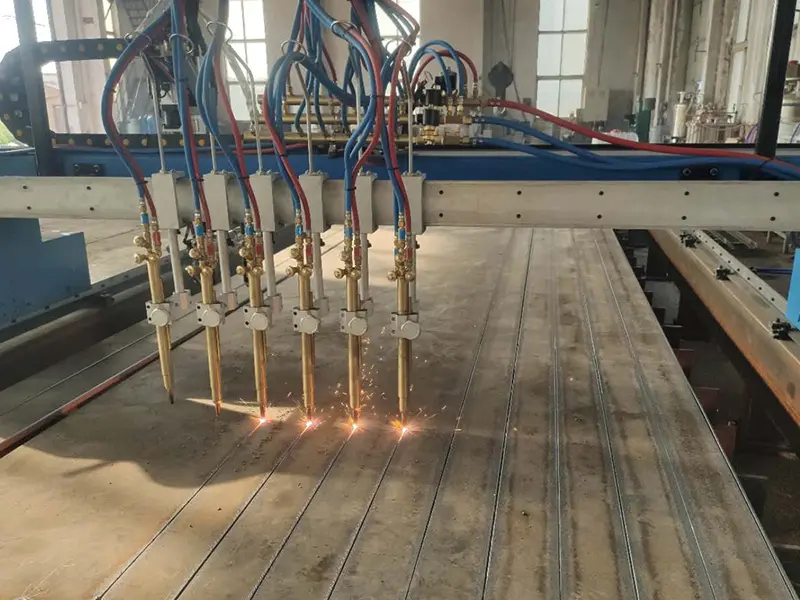

Continuous Operation for High-Volume Output

Industrial production depends on machines that can run for long hours without performance degradation. FWINCNC offers gantry and ground-rail fiber laser cutting machines as well as heavy-duty plasma cutting systems engineered for continuous workloads. Reinforced machine frames, stable transmission structures, and industrial-grade electrical components ensure reliable performance during multi-shift production. These systems are widely used in steel fabrication, machinery manufacturing, and large-scale metal processing where output consistency directly affects delivery schedules.

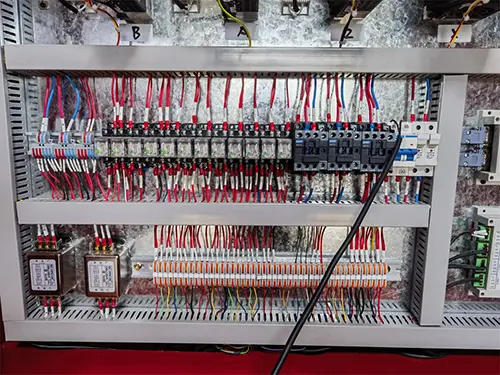

Low Failure Rate & Predictable Maintenance Cost

For industrial users, downtime is more expensive than the machine itself. FWINCNC industrial systems prioritize structural rigidity, component reliability, and simplified maintenance logic. Plasma bevel cutting machines and tube cutting systems are designed with clear mechanical layouts and proven configurations to reduce unexpected failures. Standardized parts selection and mature control systems help factories plan maintenance cycles, control spare part costs, and avoid production interruptions caused by complex or unstable designs.

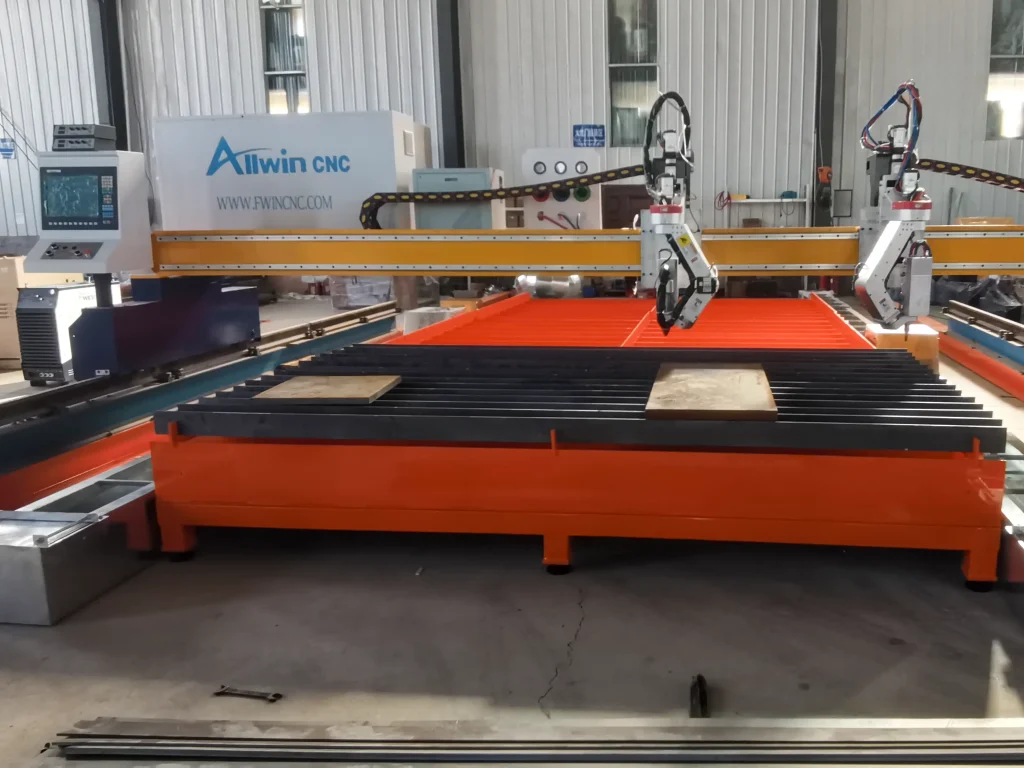

Standardized Production with Flexible Customization

Industrial factories often require standardized equipment for stable production, while still needing customization to match specific materials, sizes, or processes. FWINCNC balances both. Modular configurations allow customers to select cutting power, working length, bevel functions, and loading methods without sacrificing system reliability. From standardized laser tube cutting machines to customized large-format plasma systems, our solutions adapt to production lines rather than forcing factories to adapt to machines.

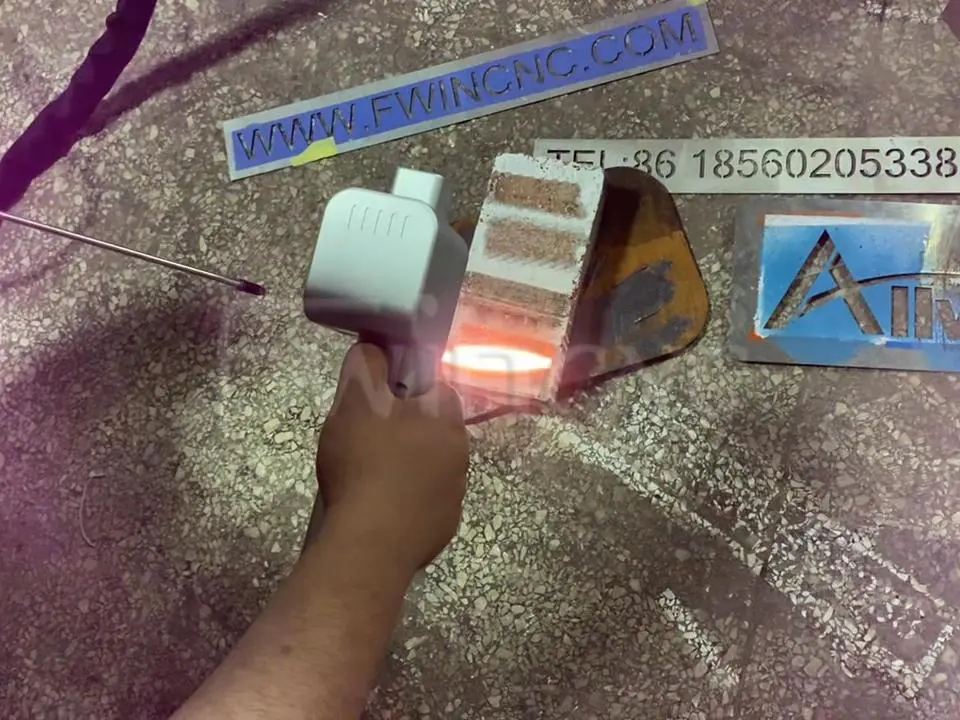

Integrated Welding & Surface Preparation for Production Lines

Industrial production does not stop at cutting. FWINCNC industrial laser welding machines and laser cleaning systems support downstream processes such as structural assembly, surface treatment, and weld preparation. Laser welding delivers high-strength joints with minimal deformation, while laser cleaning removes rust, oxide layers, and coatings without chemicals. These technologies improve workflow efficiency, reduce manual labor, and help factories maintain cleaner, safer production environments.

Built for Stability, Scale, and Long-Term Production

FWINCNC’s Cost-Saving Cutting Solutions are built around one principle: lower total cost of ownership, not just lower purchase price.

Through flexible configurations, optimized logistics, simplified maintenance, and performance-driven design, these solutions help customers cut metal efficiently while protecting cash flow and business sustainability.

Whether you are starting small, expanding carefully, or optimizing an existing workshop, FWINCNC offers cutting equipment that supports smarter investment decisions and long-term value creation.