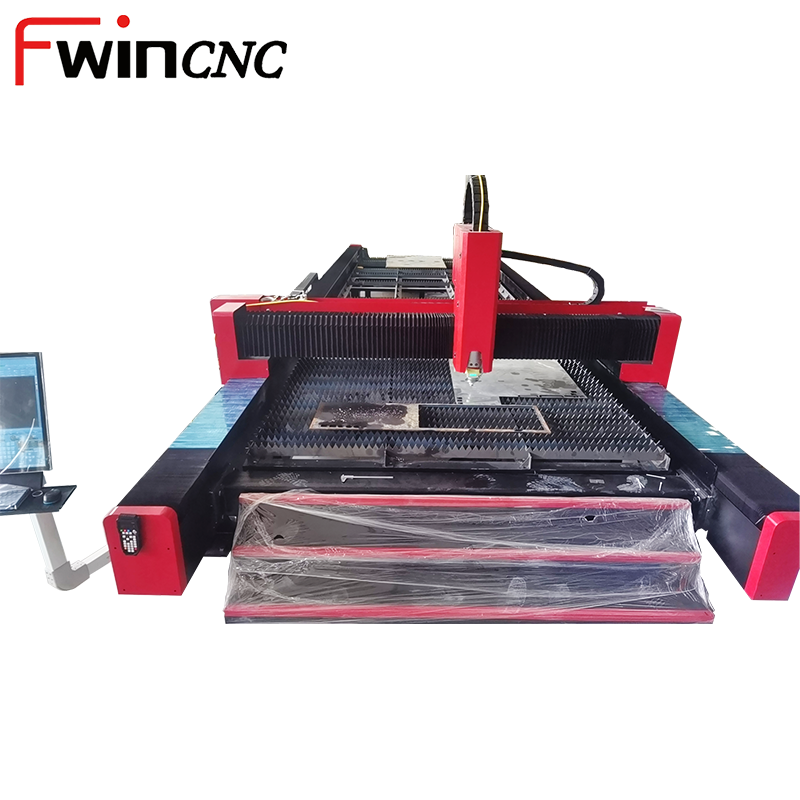

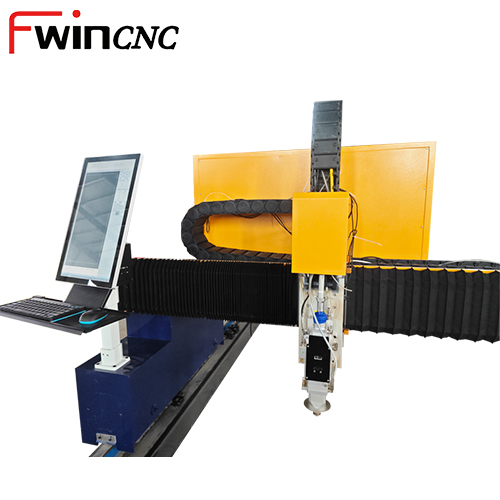

Affordable Heavy Gantry Type Laser Cutting Machine

High-Power Gantry Laser Cutter – Customizable B2B Solutions with Large Format, Precise, Efficient, and Versatile Metal Cutting Configurations

-

Large & Flexible Work Area – Heavy-duty gantry and wide-format table support oversized sheets and customizable widths for one-pass processing.

-

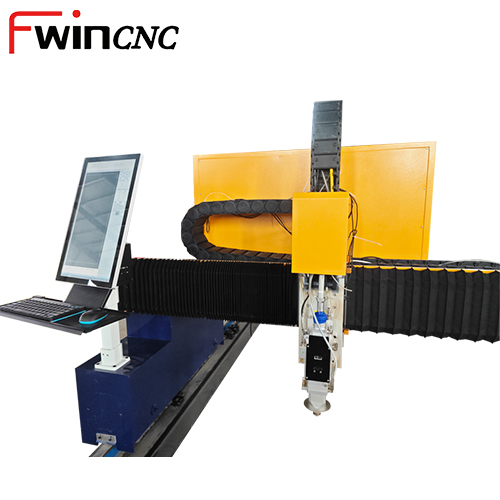

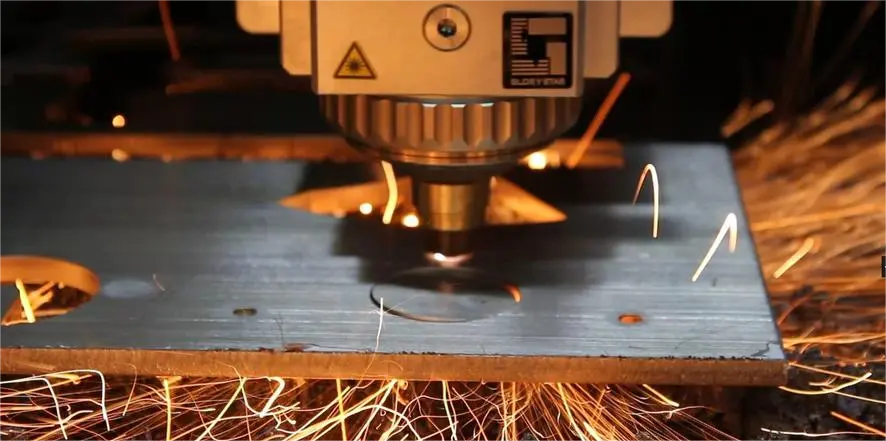

High Cutting Performance – Powerful laser handles thick and lightweight metals with precision, speed, and stability.

-

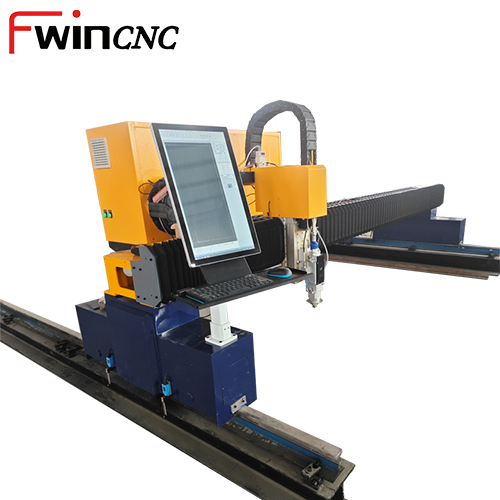

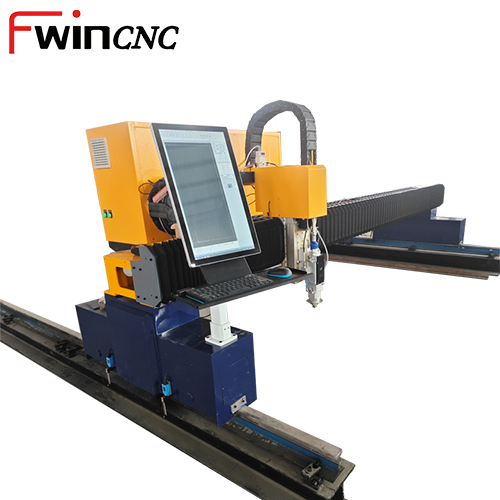

Lightweight & Rigid Structure – Aerospace-grade aluminum beams enhance stability, dynamic response, and energy efficiency.

-

Quick Installation – Modular design allows fast on-site setup without complex X/Y-axis adjustments.

-

Smart & Compatible – CNC system supports complex graphics; optional automated loading/unloading integrates into production lines.

-

Cost-Efficient & Upgradeable – Durable, low-maintenance components with open architecture for future expansions.

Heavy Gantry Laser Cutting Machine Description

Our dual-drive gantry laser cutting machine ensures exceptional stability and precision, delivering smooth movement and accurate cuts even on wide plates. The customizable format fits seamlessly into workshop spaces, maximizing efficiency and productivity.

Key advantages include:

-

High Motion Rigidity – Enhances cutting accuracy and competitiveness for workshop production.

-

Clean & Precise Cuts – Smooth cutting sections and precise small-hole cutting improve finished product quality.

-

Eco-Friendly Operation – Minimal smoke and dust reduce air pollution, creating a healthier workspace.

-

Quick Installation & Easy Maintenance – Gantry design requires minimal foundation and allows straightforward operation and upkeep.

This machine combines precision, efficiency, and environmental friendliness, making it a reliable and valuable asset for industrial metal fabrication.

| No. | machine model:ALLWIN–6000W | ||||

| 1 | Max working area | 2500mmx6000mm | |||

| 2 | Packing size | 3850mmx580mmx1100mm&1800.00kgs | |||

| 3 | Laser source | MAX BRAND 6.0KW | |||

| 4 | Laser head | Swiss RAYTOOLS with auto focus | |||

| 5 | Software | Professional raytools software | |||

| 6 | Motor and driver | HCFA Servo motor and driver | |||

| 7 | Y AXIS | 2*1300W HCFA servo motor | |||

| 8 | X AXIS | 1*850W HCFA Servo motor | |||

| 9 | Z axis | 1*400w HCFA Servo motor | |||

| 10 | Water chiller | S&A brand with Dual temperature,dual control | |||

| 11 | Working voltage for 6.0kw | 3phrase 380V with 50hz | |||

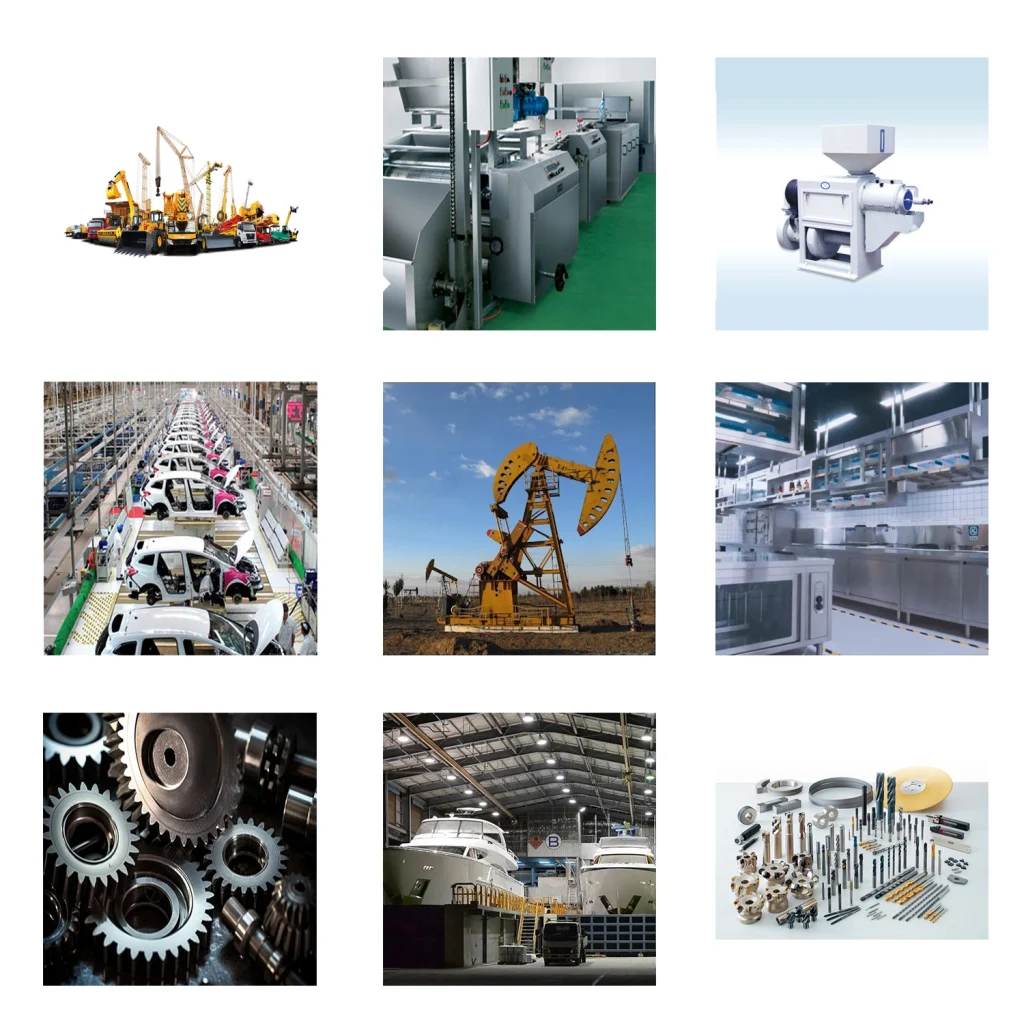

Heavy Gantry Laser Cutting Machine Applications

The heavy gantry laser cutting machine delivers efficient and precise cutting for medium to thick steel plates across diverse industries:

-

Shipbuilding & Construction Machinery – High-capacity cutting for large structural components.

-

Steel Structures & Locomotives – Precise cutting for beams, frames, and assemblies.

-

Agricultural & Forestry Machinery – Accurate processing of complex metal parts.

-

Electrical & Petroleum Equipment – Efficient production of industrial components.

-

Automotive & Tool Manufacturing – High-precision cutting for parts and tools.

-

Kitchen, Bathroom & Food Machinery – Smooth, burr-free cuts for appliances.

-

Textile Machinery & Laser Outsourcing Services – Versatile cutting for various fabrication needs.

This machine boosts productivity and precision, making it ideal for industrial B2B metal fabrication and large-scale production lines.

-

Large Processing Area – Supports cutting lengths up to 40m and widths up to 8m, ideal for batch processing of large medium and heavy plates.

-

High Precision – Fiber laser technology ensures fine, accurate cuts, even for small parts and corners.

-

Fast Processing Speed – Efficiently handles medium and heavy plates, improving productivity for large-scale projects.

-

High Material Utilization – Narrow kerfs and precise cutting allow tighter nesting, maximizing plate usage.

-

Clean Vertical Cuts – Produces vertical sections without burrs, eliminating secondary processing.

-

Eco-Friendly & Efficient – Generates less dust and smoke, ensuring a cleaner, environmentally conscious workflow.

Get Free Quote of Gantry laser cutting machine

FWINCNC’s heavy-duty gantry laser cutting machine can cut thin plates at high speed and efficiently, and cut thick plates stably and accurately. It is the perfect choice for your industrial metal cutting.

Related News

Investing in a laser cutting machine is a significant step toward enhancing your manufacturing capabilities, improving precision, and boosting productivity. […]

FWINCNC has released an enhanced generation of its Dismountable Laser Metal Cutting Machine, engineered for manufacturers that require high-precision cutting […]

What is laser ceramic ring? The ceramic ring is a commonly used accessory of laser cutting machine, the laser ceramic […]

Laser cutting machines are a valuable asset for many industries Laser cutting machine is a valuable asset for many […]

In recent years, the advent of portable laser cutting machines has significantly transformed the landscape of precision cutting in various […]

1. Prevention of Laser Condensation Laser cutting machinery requires water cooling for both laser and optical components. Given the high […]

The application of laser technology has emerged as a game-changer in the manufacturing processes of automobiles The automotive industry has […]