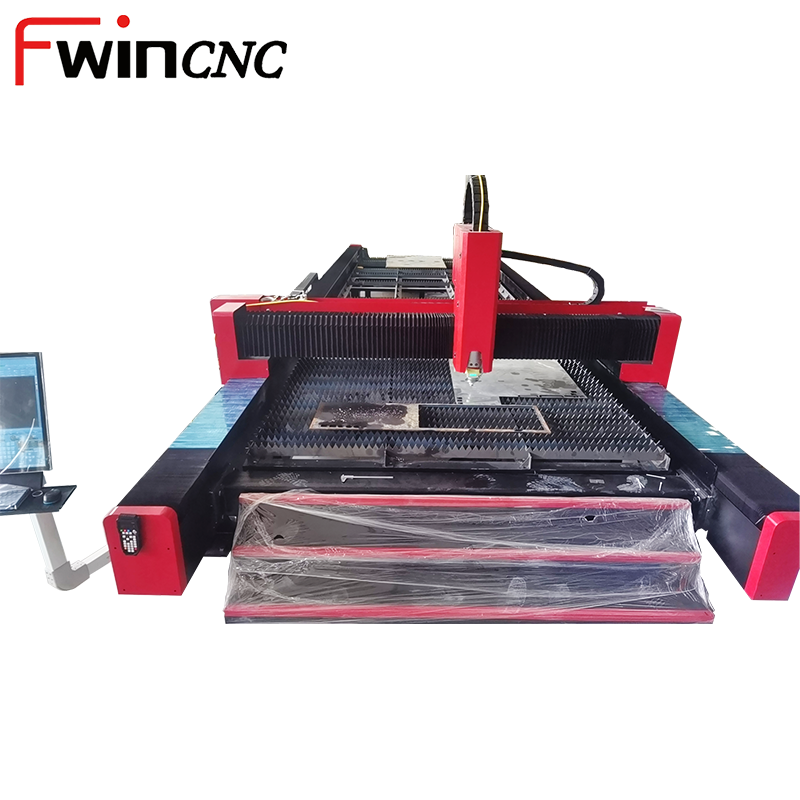

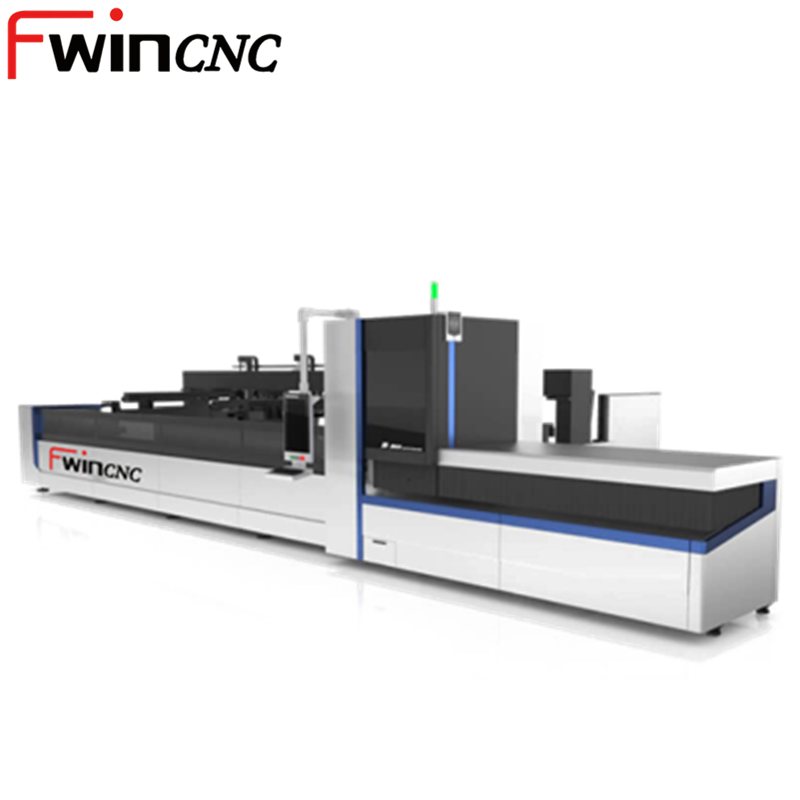

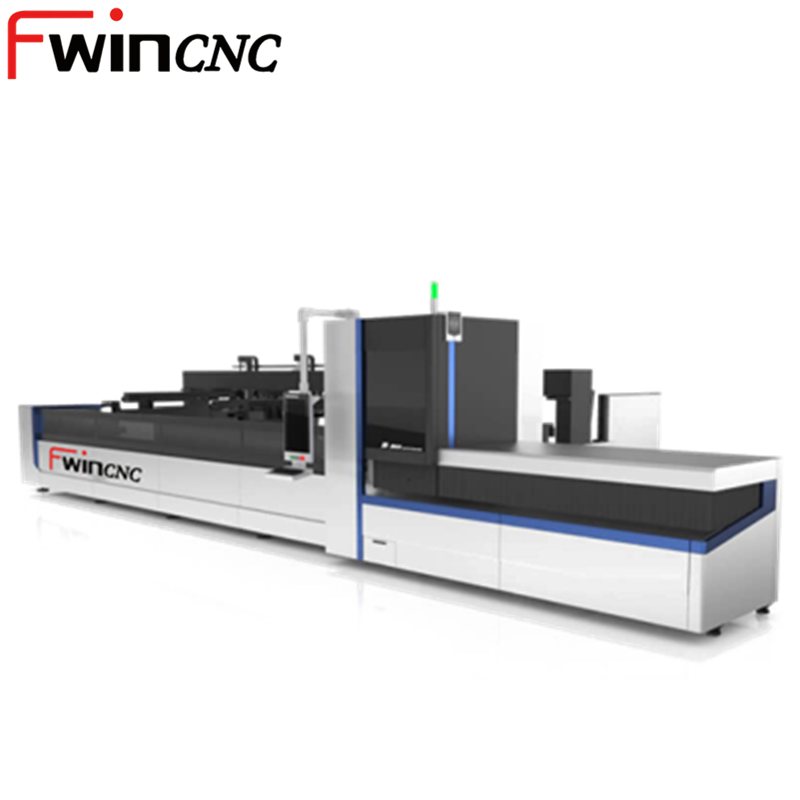

Heavy Duty Metal Tube Laser Cutting Machine

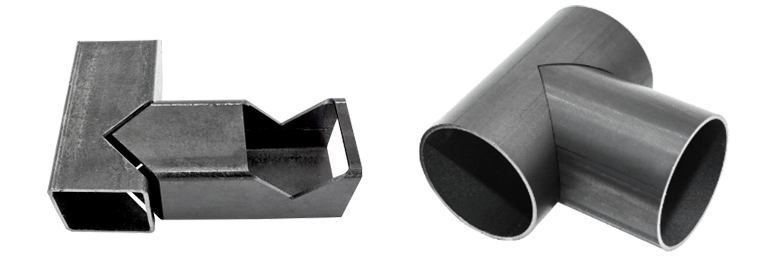

Metal Tube Fiber Laser Cutting Machine equipped with a pneumatic self-centering chuck, the structural design is simple and stable, and it can clamp various profiles such as rectangular tubes and round tubes;

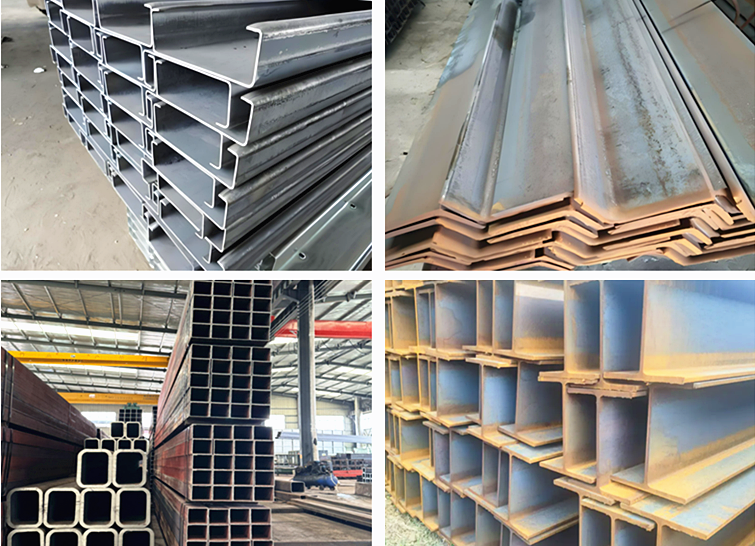

Heavy Duty Metal Tube Laser Cutting Machine could cut more different kinds of pipe shapes e.g: Round pipe.square pipe/ Rectangular shape/H shape/C shape.

Features of Heavy Duty Metal Tube Laser Cutting Machine

1.Strong applicability: can cut square tube and round pipe

2.Pneumatic chuck: More stable

3.Save material: the tail material is short to 40-60mm, saving material cost

4.Feeding system: batch feeding, fast feeding speed

5.Follow-up support: Independent servo follow-up support, to provide support when cutting pipe to prevent sagging, to ensure cutting accuracy

6.Cutting sample: can cut round tube, square tube, rectangular tube, hexagonal tube, shaped tube and so on

Heavy Duty Metal Tube Laser Cutting Machine Description

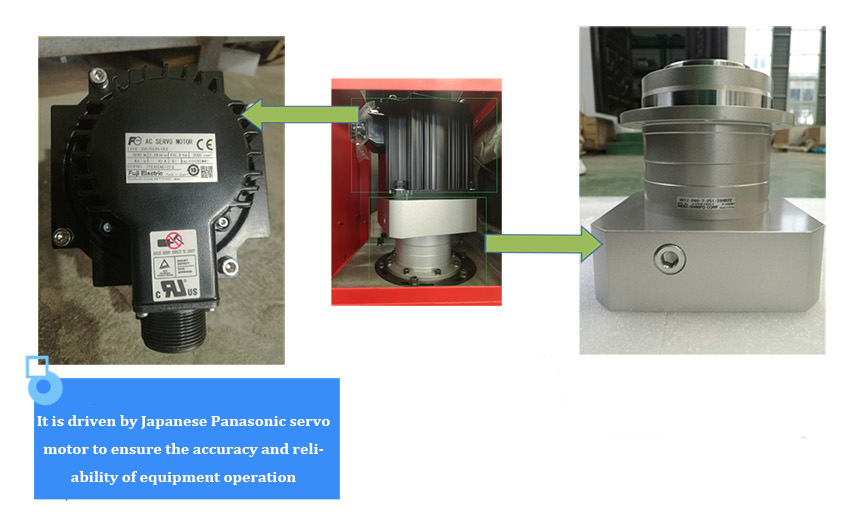

1. Driven by dual servo motors.

2. Offering enhanced stability, increased speed, and accelerated acceleration.

3. Utilizing fully digital CNC servo motor communication.

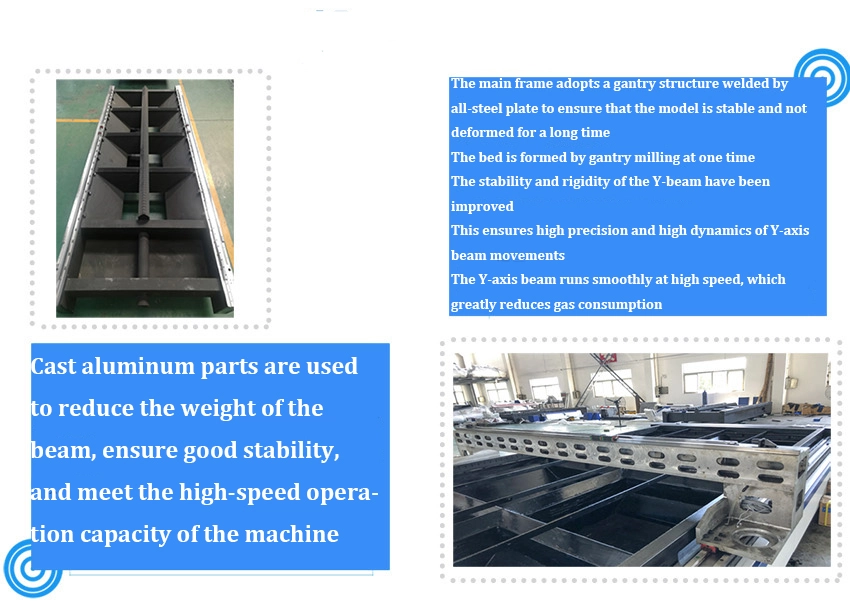

4. The machine features a gantry structure, with imported gantry milling and finishing to ensure it remains deformation-free for 20 years of regular usage.

5. The bed is constructed with an integral welded structure, undergoing annealing for roughing and subsequent vibration aging treatment. This process effectively eliminates welding and processing stress, resulting in excellent rigidity, high precision, and long-term deformation resistance.

6. Incorporating a Japanese SMC intelligent gas group design, enabling automatic pressure regulation, air exchange, pressure detection, and other functionalities.

7. The guide rail and rack undergo precision collimator calibration, ensuring an accuracy level of ±0.02mm.

| Product Name | Heavy Duty Metal Tube Laser Cutting Machine |

| Working size | Round pipe diameter: Ф16-Ф500mm Square tube diagonal: Ф16-Ф300mmRectangular: long side ≤250mmMaximum cutting length:12m Minimum cutting length: 2m Shortest remaining material:80mm |

| Packing dimension | 2250mmx3700mmx1700mm |

| Weight for machine | 2700KGS |

| Laser Source | World Famous Fiber Laser Source (Raycus/Max/ IPG) |

| Laser head | Swiss RAYTOOLS BM111 with autofocus(for other option) |

| software | Cypcut software |

| controller system | Professional FSCUT 3000 |

|

Motor and driver |

servomotors X,Y 850W+400W Z axis |

| rotary axis use 3000w servo motor | |

| Reducer | Japan SHlMPO reducer |

| Water chiller | HANLl brand with Dualtemperature,dual control |

| Rack and pinion | Taiwan brand T-WlN rack and pinion |

| Gantry type | Aluminum cast gantry |

| Transmission Method | High Precision Gear Transmission |

| Transmission type | Gear rack transmission system |

| Maximum ldle Speed | 90m/min |

| Repeated Positioning Degree | ≤±0.02mm |

| Focus Method | Dynamic Auto-Focusing System |

| Working voltage | 380v50Hz+10% |

Heavy Duty Metal Tube Laser Cutting Machine Applications

Fields of application

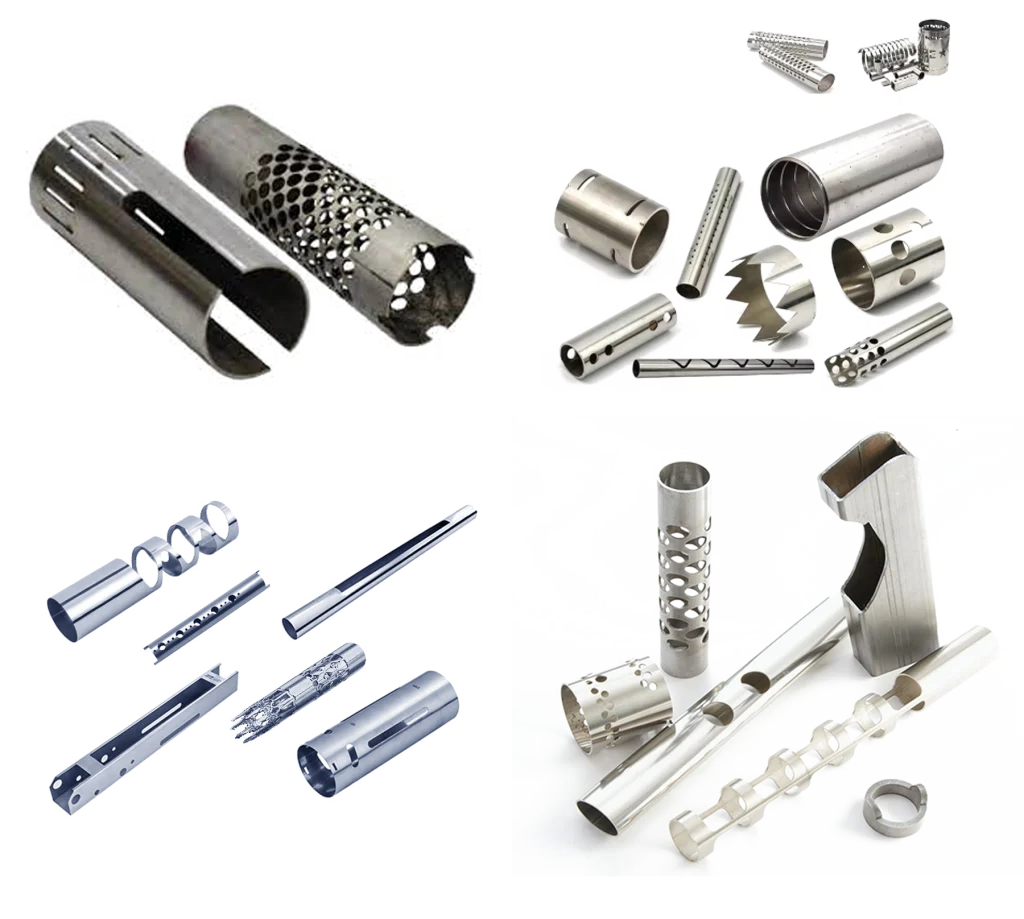

Heavy Duty Metal Tube Laser Cutting Machines are primarily used for precise cutting and processing of metal thin-walled pipe fittings, including metal staircase handrails, stainless steel bathroom pipe fittings, drying racks, sports equipment, medical equipment, car frames, anti-theft nets, sports bicycles, water purifiers, furniture industry, automobile exhaust pipes, greenhouse pipes, guardrails, shelf pipes, and more.

Applicable materials

The materials that can be worked on include carbon steel, stainless steel, alloy steel, aluminum and alloys, copper and alloys, titanium and alloys, nickel-molybdenum alloys, and others.

With the prevailing inclination towards intelligent manufacturing and the swift advancement of the laser industry, laser technology and laser products are progressively reaching a state of maturity. Laser processing disrupts conventional processing techniques, aiding enterprises in their transformation and upgrade endeavors, while also expediting the progress of intelligent manufacturing. The conventional approach to pipe processing involves numerous steps such as sawing, milling, punching, and drilling. In contrast, laser pipe cutting necessitates only a single piece of equipment and one operator, resulting in a significant enhancement in efficiency, cost reduction, and the establishment of a competitive edge.

Laser pipe cutting is widely used in all walks of life, with continuous innovation and breakthrough in pipe splicing technology, which can realize riveting, round pipe intersection line, square pipe bending and overlap, bevel cutting and overlap and other processes.

1.Riveting

It can realize riveting of round tubes to round tubes, square tubes to square tubes, square tubes to round tubes, etc.

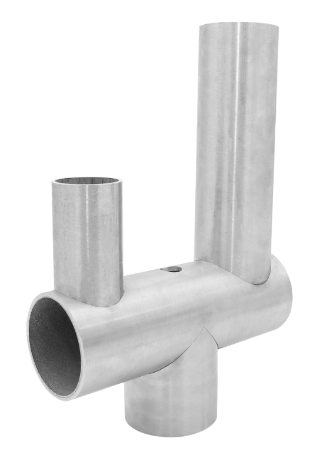

2. Round tube intersection line

Round pipe intersecting line cutting is mostly used for pipe cutting in industries such as electric vehicles and bicycles.

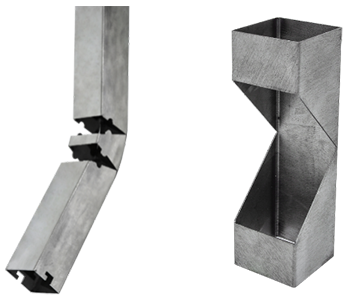

3. Square tube bending lap

The square tube can be programmed to achieve V, R mouth cutting, after bending, the joint can be small, direct post-process welding, mostly used in the furniture industry.

4. Bevel cutting and overlapping

The bevel cutting head achieves ±45-degree swing cutting and tight splicing to ensure subsequent welding accuracy.

Get Free Quote of Heavy Duty Metal Tube Laser Cutting Machine

Tubes are used everywhere – from mechanical engineering and system construction all the way to the furniture industry. Lasers have opened up new design possibilities, so more and more designers are taking advantage of the benefits of laser-cut tubes thereby considerably increasing demand. Discover all-round solutions for the world of laser tube cutting and find out more about the FWINCNC laser tube cutting machines.

Related News

FWINCNC, a leading manufacturer of CNC laser and plasma cutting machines, proudly launches its new Square and Round Tube Laser […]

Laser cutting machines are a valuable asset for many industries Laser cutting machine is a valuable asset for many […]

In recent years, the advent of portable laser cutting machines has significantly transformed the landscape of precision cutting in various […]

The application of laser technology has emerged as a game-changer in the manufacturing processes of automobiles The automotive industry has […]