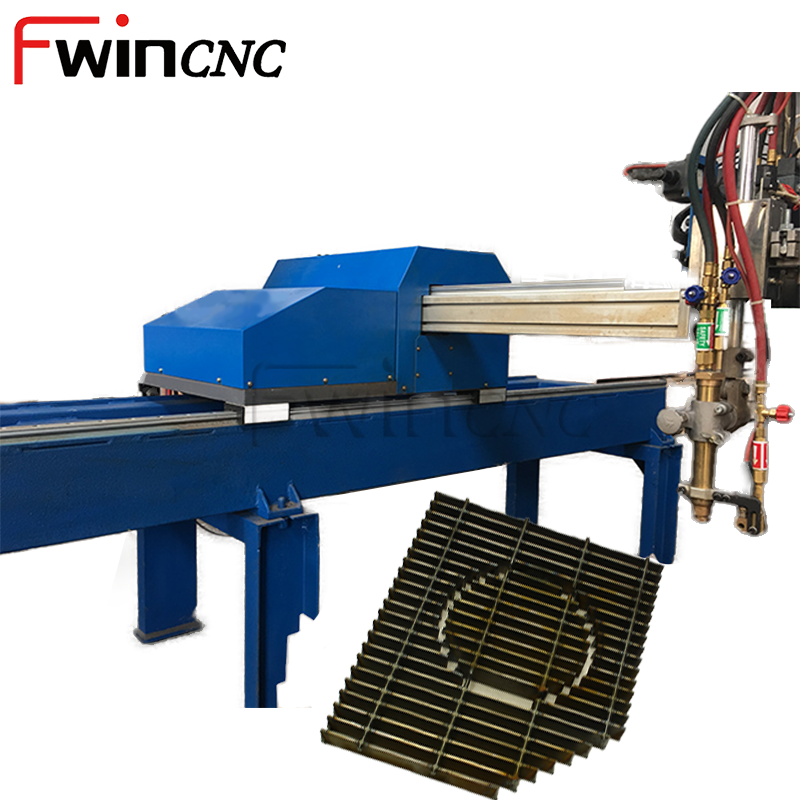

Portable Gantry Plasma Cutting Machine Sheet Pipe Metal Tube

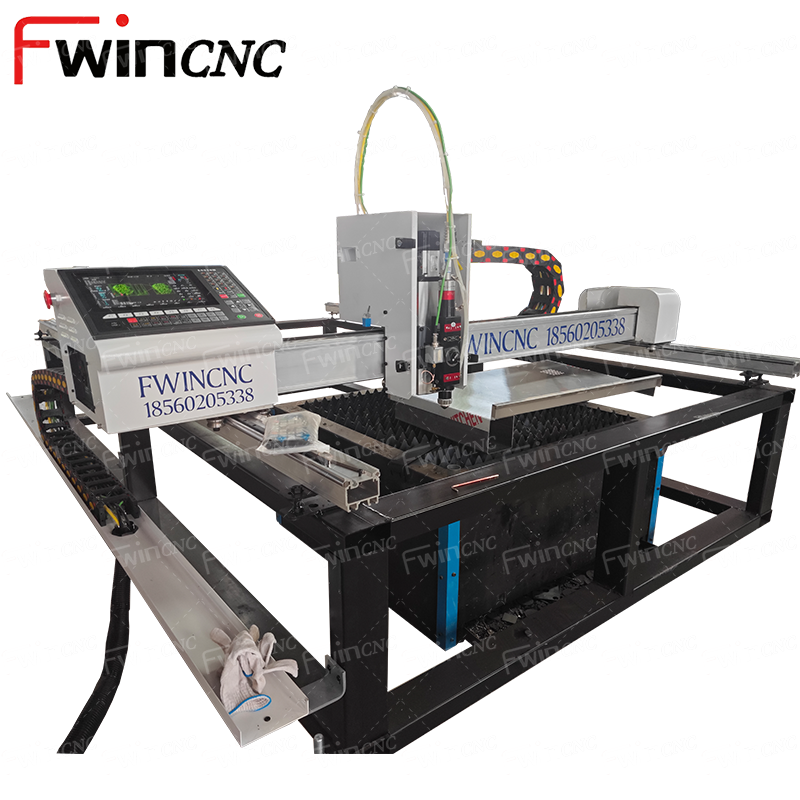

Our Dual Drive Gantry Plasma Cutting Machine is designed for heavy-duty cutting, capable of handling both plate and pipe cutting with exceptional precision. With a cutting width of 2000mm and cutting length up to 6000mm, this machine features a rotary attachment and is equipped with plasma and optional flame cutting modes. It is a robust, versatile solution for industries requiring high cutting speeds and customizable settings.

-

High Cutting Capacity

Supports both sheet metal and round pipes with diameters up to 410mm and lengths up to 6 meters. -

Dual Drive Precision

Equipped with stepper motors for high precision cutting, ensuring clean cuts and minimizing dross. -

Automatic Torch Height Control

Features an automatic THC (Torch Height Controller), providing consistent cut quality and prolonging consumable lifespan. -

Easy Operation

Controller and Hinest software for pipe cutting and Fastcam for flat sheet cutting, making the system user-friendly. -

Durable and Reliable

Built with a strong CNC frame and electrical components, ensuring long-lasting performance and stability under heavy workloads.

Our Dual Drive Gantry Plasma Cutting Machine is engineered for precision and durability, making it the ideal solution for both plate cutting and pipe cutting in heavy industrial environments. With a cutting width of 2000mm and a cutting length of up to 6000mm, this machine can handle large materials with ease, offering both plasma cutting and optional flame cutting capabilities. The integrated rotary attachment allows the machine to effortlessly process round pipes with diameters up to 410mm.

Precision and Flexibility: Equipped with stepper motors, this plasma cutter delivers high-speed cutting with remarkable accuracy (±0.1mm). It also features automatic torch height control (THC), ensuring consistent cutting quality and minimizing the wear on consumables. The machine’s versatility allows it to be adapted for a range of materials and applications, making it an indispensable tool for industries such as automotive manufacturing, metal fabrication, and construction.

User-Friendly Control: The system is powered by FANGLING controller system and enhanced with Hinest software for pipe cutting and Fastcam for flat sheet cutting. This makes the machine simple to operate, even for less experienced users. With a USB transmission method and automatic design patterns, you can begin cutting in no time.

Built for Longevity: The strong CNC frame and CHINT electrical components ensure stability under heavy loads, reducing maintenance and improving operational uptime. With a cutting speed range of 100~6000mm/min, this machine is designed for both high precision and high productivity, allowing you to cut large volumes of material quickly and efficiently.

Maximized Efficiency: The machine is designed for minimal setup and fast operation, helping businesses streamline their production process and reduce labor costs. The optional plasma power setting allows for flexibility in cutting material thickness and type, making it suitable for a wide range of applications.

By choosing the Dual Drive Gantry Plasma Cutting Machine, you are investing in a reliable, high-performance solution that will increase productivity, reduce operational costs, and provide you with top-quality cuts every time.

| No. | Model FW-ST400*12 | for heavy strong round pipe | |||

| 1 | metal pipe | diameter 50mm-400mm | |||

| 2 | Pipe length | 12000mm | |||

| 3 | Cutting Mode | Plasma | |||

| flame for option | |||||

| 4 | Rotary attachment | chuck diameter 320mm-1pcs | |||

| 5 pcs supporting legs | |||||

| 4.914285714 | Driving and motor | stepper motor to support 1100kgs loading pipe | |||

| 5.772413793 | loading capacity for pipe | customerized | |||

| 7.040394089 | lifting method | manual | |||

| Controller system | one set of startfire | ||||

| 8.308374384 | Height controller | startfire 2100 | |||

| rotation speed | 0.1-25r/min | ||||

| 9 | position accuracy | ±0.1mm | |||

| 10 | running accuracy | ±0.2mm | |||

| 11 | cutting speed | 0-6000mm/min | |||

| 12 | Torch height controller | Automatic THC for plasma ZHONGYU 2020 | |||

| 13 | input power | 220±10%V AC50HZ/60HZ | |||

| 14 | tramsmission method | USB | |||

| Software | HiNest Technology pipe | ||||

| 15 | programe software | AutoCAD/CAM | |||

| 16 | Electrical components | CHINT | |||

| 17 | machine size (L*W*H) | 14000mm*1400mm*1500mm | |||

| 18 | package size (L*W*H) | 8000mm*1400mm*1500mm | |||

Ideal for industries such as metal fabrication, automotive manufacturing, construction, and pipe production. Perfect for projects requiring high-speed, precise, and cost-effective cutting solutions.

The Dual Drive Gantry Plasma Cutting Machine is designed to meet versatile industrial demands, offering both plasma and optional flame cutting for multiple material types. Its compact design ensures easy setup and transportation, while the advanced control system guarantees reliable and consistent performance. Choose this machine to improve your production efficiency, reduce operational costs, and enjoy enhanced cutting precision.

Ready to optimize your cutting process? Contact us for more details or request a quote.