Pulse Laser Spot Welding Machine

Portable pulse laser spot welder for precise, low-heat, deformation-free welding of small metal parts with long-life modular design.

- Ultra-low heat input, no deformation

- High-precision welding for small components

- Self-developed long-lifespan laser source

- 13 kg portable, air-cooled, desktop-friendly

- Minimalist knob-control interface, adaptive cooling

Pulse Laser Spot Welding Machine Description

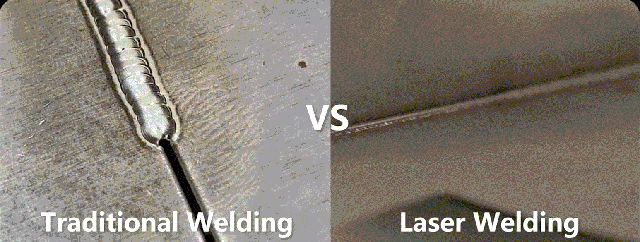

Pulse laser spot welding uses short, concentrated bursts of energy to melt a micro-sized area of metal, creating a precise weld with minimal heat transfer to surrounding material. This technology avoids the broad heat-affected zones and distortion seen in traditional welding methods. The process keeps the weld surface clean, reduces post-processing, and supports consistent accuracy on small components.

Choosing a pulse laser spot welder is a technical decision driven by control and stability. The energy delivery is quantized and repeatable, allowing reliable weld formation even on thin or heat-sensitive metals. The localized thermal impact preserves structural integrity, enabling high-precision joining where deformation, discoloration, or warping must be avoided. The method also improves long-term production consistency because each pulse is identical in duration and intensity.

This model integrates a self-developed, high-reliability laser source engineered for long service life and stable optical output. The 13 kg air-cooled architecture eliminates external chillers and reduces maintenance variables. The interface uses a simplified, knob-based parameter system to cut operational overhead and shorten learning time. Adaptive fan control regulates internal temperature according to the working environment, ensuring continuous output stability. With a 0.2–2 mm effective welding thickness range, the system meets the requirements of precision metalwork, small components, repair tasks, and fine manufacturing workflows.

| Product Model | FW-600W/FW-1200W | ||||

| Laser power | 600W/1200W | ||||

| Fiber length | Length: 2 meters | ||||

| Working style | Pulse | ||||

| Cooling mode | Air cooler | ||||

| Welding materia | carbon steel,stainless steel,galvanized sheet steel,aluminum |

||||

| Welding thickness | 0.2-2mm | ||||

| Work environment | -20℃-35℃ | ||||

| Working voltage | 220V 50Hz/60Hz | ||||

| Maxim Power Consumption | <2.5KW | ||||

| Net Size/Weight | 390x192x269mm/13KG | ||||

| Pack dimensions//Weight | 540x310x380mm/16KG | ||||

| Pack | Carton |

Portable air-cooled pulse laser spot welding machine applications

Traditional welding applies broad, continuous heat, causing large heat-affected zones, distortion, discoloration, and higher post-processing. Precision on thin metal is limited, and repeatability depends heavily on operator skill. Pulse laser spot welding concentrates energy into short, controlled bursts, producing clean micro-welds with minimal thermal spread. Thin or sensitive metals maintain structural integrity, and welds form with tighter tolerances. Output is repeatable, surface remains smooth, and deformation is negligible. For small components, electronics, fine repair, and high-accuracy manufacturing, laser spot welding delivers higher precision, stability, and process efficiency.

Get Free Quote of Laser Spot Welder

Delivers precision, portability, and reliability for users needing stable micro-welding without complex training or bulky equipment. Supports fast deployment, clean operation, and long service life. Drives higher yield, lower rework rates, and improved quality control. Guide users to submit inquiry for specifications, samples, and pricing.

Related Products

Related News

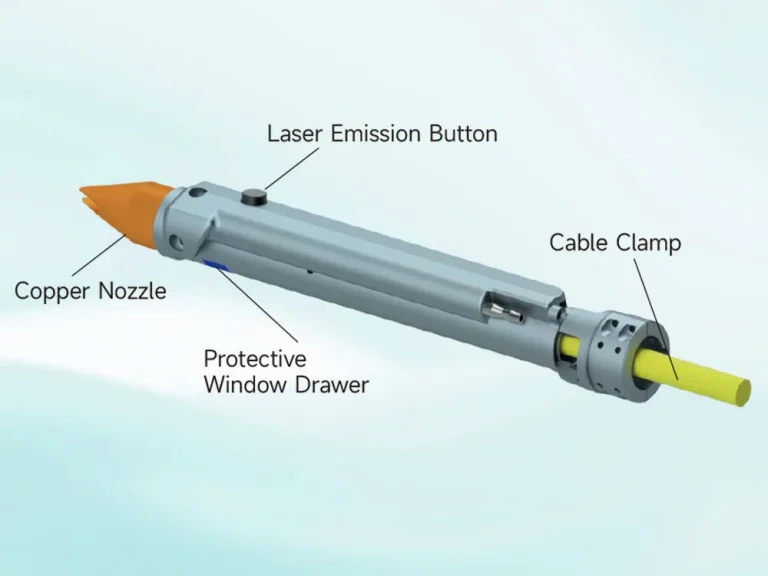

What is Laser Welding Nozzle? The nozzle of a laser welding machine is an essential component located at the end […]

Fiber lasers account for an increasing share of industrial lasers year by year due to their simple structure, low cost, […]