Low-Frequency vs. High-Frequency Plasma Power Supplies

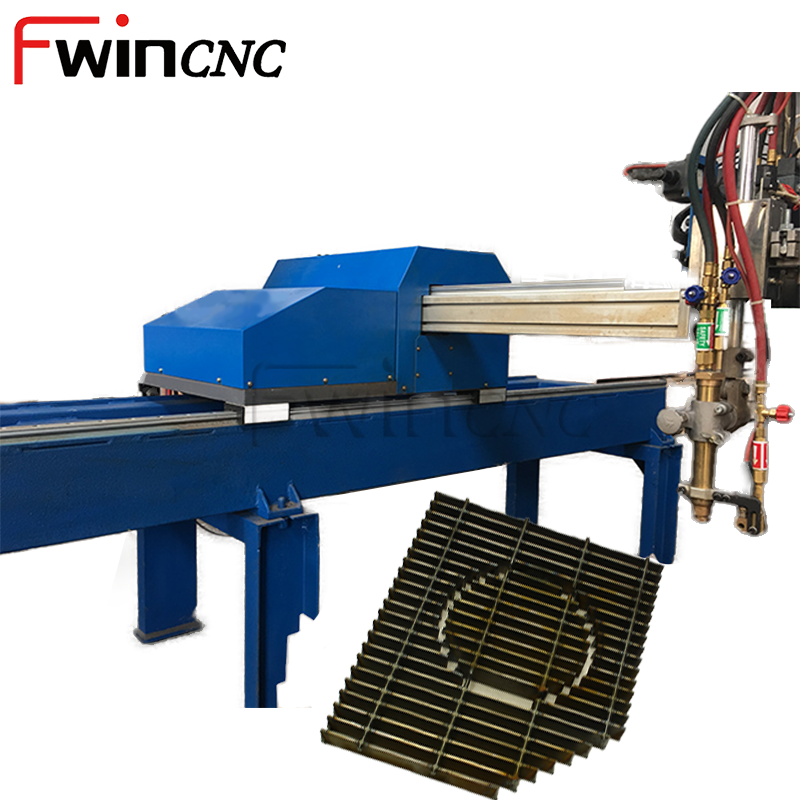

Low-frequency plasma power supplies are known for their simple structure, strong reliability, and lower electromagnetic interference. They are commonly used in CNC plasma cutting systems where signal stability is important. These models are ideal for users who prioritize system compatibility, stable operation, and cost control.

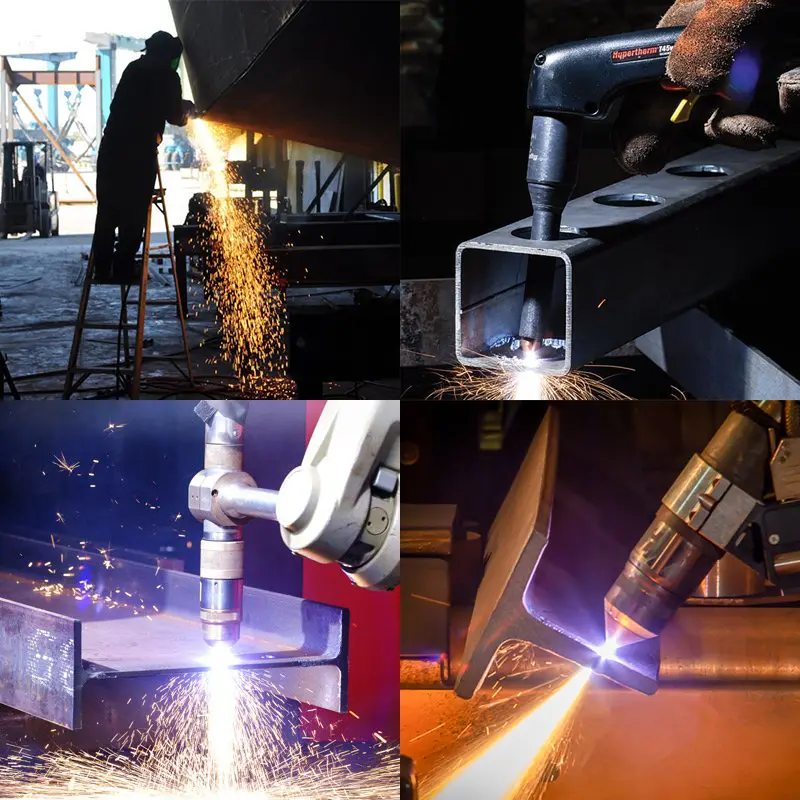

High-frequency plasma power supplies provide easier arc ignition and stronger cutting capability, especially for thicker materials. They are widely used in manual cutting and heavy-duty industrial applications where fast piercing and high cutting power are required. With current options extending up to 500A, high-frequency models are suitable for large-scale fabrication and thick plate processing.

Choosing between low-frequency and high-frequency depends on the cutting environment, automation level, and material thickness. Both types are designed to deliver reliable performance when matched with the correct application.