Investing in a laser cutting machine is a significant step toward enhancing your manufacturing capabilities, improving precision, and boosting productivity. But with a wide array of options on the market, how do you select the perfect machine for your specific needs? This comprehensive guide will walk you through the key factors to consider, ensuring you make a smart, profitable investment.

1. Identify Your Primary Materials and Thickness

The first and most crucial step is to define what you will be cutting. The type and thickness of the material directly determine the required laser source and power.

-

CO2 Lasers: Ideal for non-metallic materials like acrylic, wood, leather, and plastics. They are a versatile choice for signage, crafts, and custom fabrication.

-

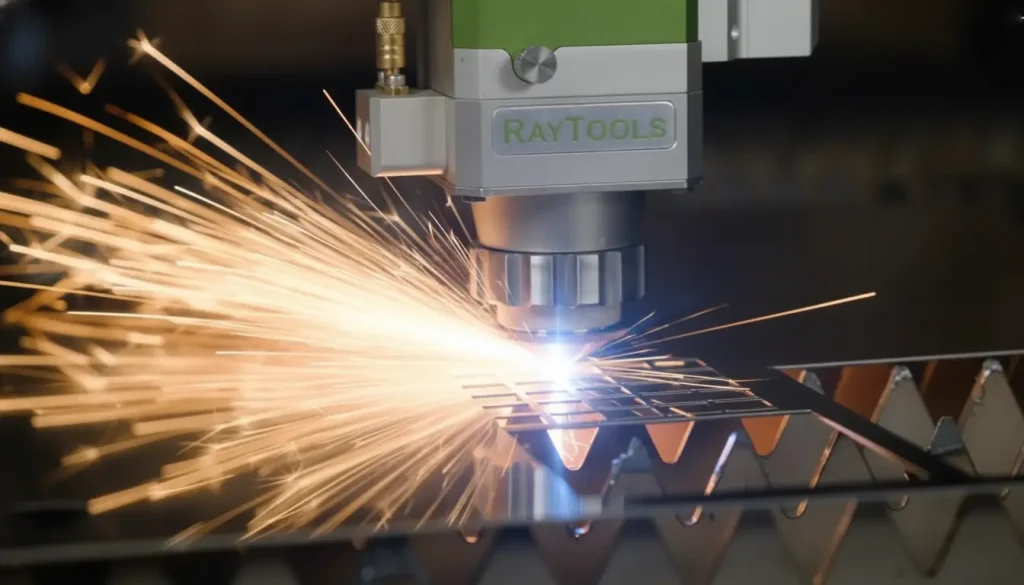

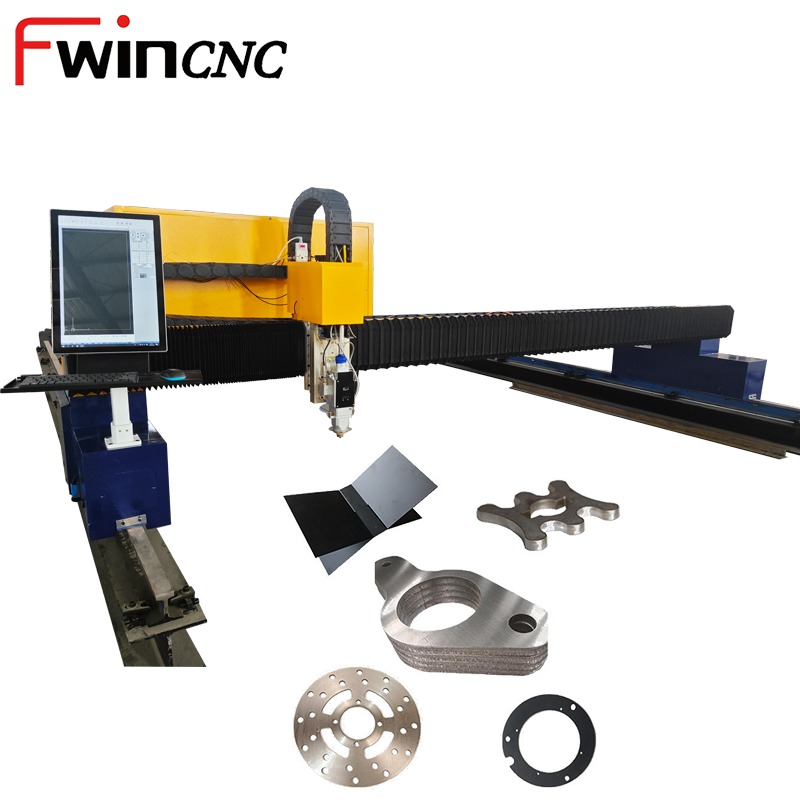

Fiber Lasers: The go-to solution for cutting metals, including stainless steel, carbon steel, aluminum, and brass. A high-power fiber laser cutting machine is essential for processing thick metal sheets efficiently.

Pro-Tip: Create a list of your most common materials and their maximum thickness. This will be your primary filter when evaluating a metal laser cutter.

2. Determine the Required Machine Size and Format

Consider the size of the raw materials you typically work with. The machine’s workbed size should comfortably accommodate your largest sheets to minimize material repositioning and waste.

-

Small-Format Machines: Perfect for workshops with limited space, jewelry making, or producing small, intricate parts.

-

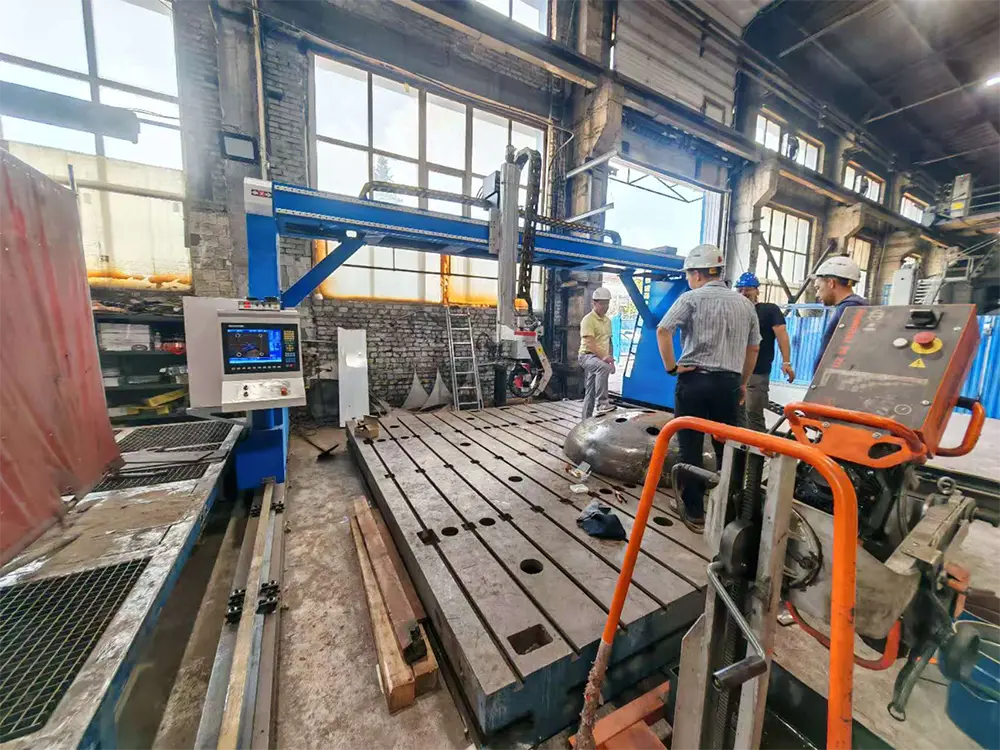

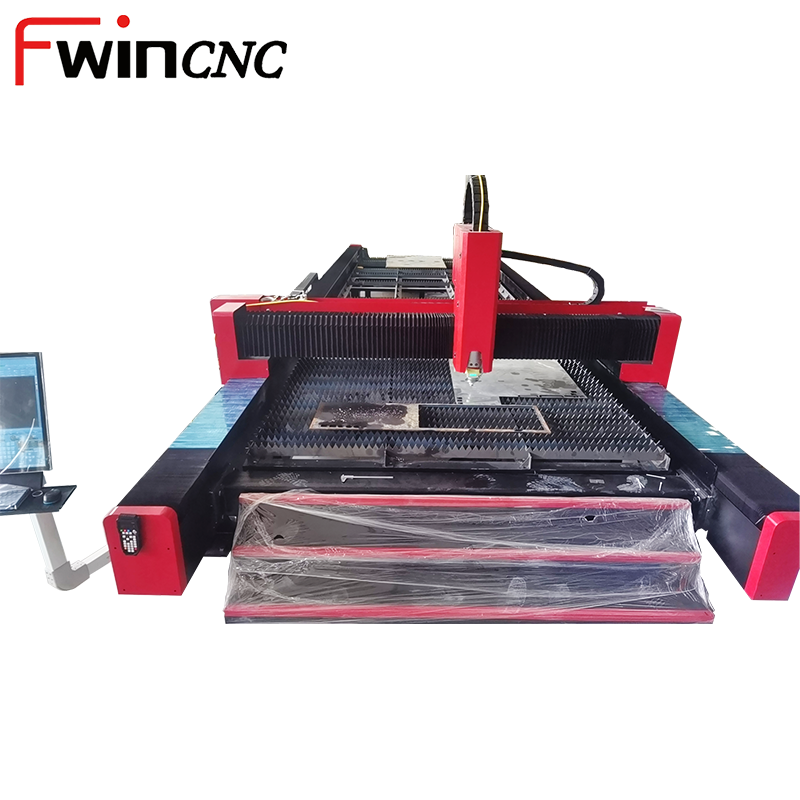

Large-Format Machines: Necessary for industrial applications like automotive parts, aerospace components, or large-scale architectural metalwork. A large format laser cutting table offers greater flexibility and efficiency for substantial projects.

-

Detachable/Modular Machines: For workshops with access limitations or those requiring portability, a detachable laser cutting machine offers a unique advantage, allowing for easier transport and installation without compromising stability.

3. Evaluate Laser Power (Wattage)

Laser power, measured in watts (W) or kilowatts (kW), dictates both cutting speed and thickness capacity.

-

Lower Power (e.g., 1kW – 3kW): Suitable for thin metal sheets (typically under 10mm). A 1.5kW fiber laser cutter is a popular choice for cost-effective, high-precision work on thinner materials.

-

Medium Power (e.g., 4kW – 6kW): A balanced option for cutting a wide range of thicknesses with good speed and quality.

-

High Power (e.g., 12kW+): Required for industrial-grade cutting of thick plates (over 20mm), offering maximum speed and productivity. When searching for a solution for heavy plate cutting, high wattage is non-negotiable.

4. Assess Software, Control Systems, and Usability

A powerful machine is only as good as its control system. User-friendly software like CypCut or Empowernot only simplifies operation but also optimizes cutting paths to save time and material.

Look for features like:

-

Intuitive user interface (UI)

-

Compatibility with standard design files (DXF, AI, DWG)

-

Nesting capabilities to maximize material usage

-

Real-time monitoring and diagnostics

5. Don’t Overlook After-Sales Support and Service

Your relationship with the manufacturer doesn’t end after purchase. Reliable after-sales support is critical for long-term operational success. Before you buy a laser cutting machine, ask about:

-

Installation and Training: Does the supplier provide on-site setup and comprehensive operator training?

-

Warranty: What is covered and for how long?

-

Technical Support: Is there a responsive team of engineers available to troubleshoot issues?

-

Spare Parts Availability: How quickly can you get critical components to minimize downtime?

At FWINCNC, we pride ourselves on providing robust, life-long technical support to ensure your machine runs at peak performance, always.

6. Why Choose FWINCNC for Your Laser Cutting Needs?

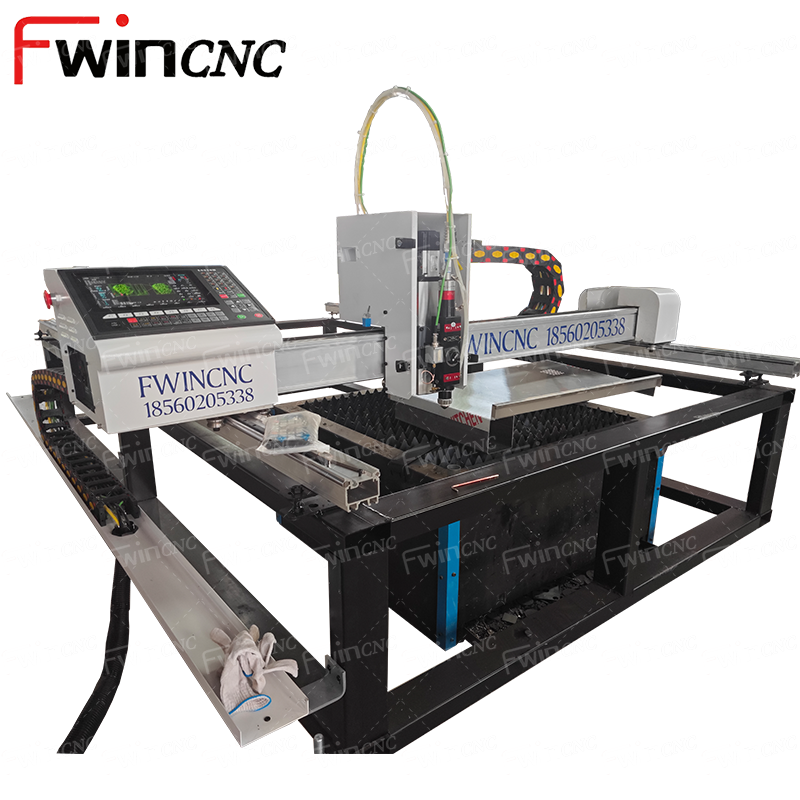

Making the right choice means partnering with a manufacturer who understands your challenges and delivers reliable solutions. At FWINCUT, we don’t just sell machines; we provide complete metal fabrication solutions.

Our range includes:

-

High-Precision Fiber Laser Cutters: Engineered for unmatched accuracy and speed.

-

Detachable Laser Cutting Machines: Offering ultimate flexibility for any workshop.

-

Tube Laser Cutting Machines: For complex tubular and profile processing.

Every machine is built with world-class components and backed by our commitment to quality and customer success.

Choosing the right laser cutting machine is a strategic decision. By evaluating your materials, size requirements, power needs, and the reliability of the supplier, you can confidently select a machine that will serve as a cornerstone of your business for years to come.

Ready to find the perfect laser solution for your business?

[Contact our experts today] for a free consultation, or [explore our full range of laser cutting machines] to see what FWINCNC can do for you.