The fiber laser cutting machine lens is a critical component in modern laser metal fabrication. It focuses the laser beam onto the material surface, enabling clean, precise cuts while maintaining efficiency and reducing heat-affected zones. Whether you are cutting stainless steel, aluminum, or carbon steel, the lens determines the overall performance of the cutting machine.

A well-maintained lens ensures consistent cutting quality, reduces maintenance costs, and prolongs the life of the laser system. In this article, we’ll explore the types of fiber laser lenses, their importance, maintenance tips, and signs that indicate replacement is needed.

Types of Fiber Laser Cutting Machine Lenses

Protective Lens

The protective lens is located closest to the workpiece. Its primary function is to shield the focusing lens from molten spatter, smoke, dust, and debris produced during cutting. Over time, the protective lens may become contaminated or scratched. Regular inspection and replacement are essential to prevent damage to the focusing lens.

Focusing Lens

The focusing lens concentrates the laser beam to a precise focal point, allowing high-accuracy cuts on various materials. Focal lengths and coatings differ depending on the laser’s power and the material being cut. For example, a shorter focal length lens improves precision for thin sheets, while a longer focal length lens is better suited for thicker plates.

Why the Lens is Crucial for Performance

A quality fiber laser cutting machine lens:

-

Ensures clean, smooth, and precise cuts

-

Optimizes energy usage, reducing wasted laser power

-

Maintains consistent cutting speed and edge quality

-

Protects other optical components by minimizing stray light

Neglecting lens care can result in rough edges, slower cutting, and potential damage to the laser system.

Maintenance Tips for Fiber Laser Lenses

Proper maintenance of your fiber laser lens prolongs its life and guarantees optimal cutting performance:

-

Regular Cleaning – Use lens cleaning wipes or alcohol-based solutions to remove dust and debris. Avoid touching the lens surface with bare hands.

-

Frequent Inspection – Look for scratches, discoloration, or burn marks. Damaged lenses should be replaced immediately.

-

Replace Protective Lens First – Protecting the focusing lens saves costs and prevents further machine issues.

-

Proper Storage – Store spare lenses in a clean, dry, and dust-free environment.

By following these maintenance practices, operators can maintain cutting accuracy, reduce downtime, and improve overall productivity.

Signs Your Lens Needs Replacement

-

Uneven or rough cutting edges

-

Decreased cutting speed despite normal settings

-

Excessive smoke or molten spatter during operation

-

Visible scratches or burn marks on the lens

Timely replacement of worn lenses ensures safe operation and prevents damage to expensive components of the laser cutting machine.

Choosing the Right Fiber Laser Lens

When selecting a fiber laser cutting machine lens, consider the following factors:

-

Material Compatibility: Lenses with specific coatings may be required for stainless steel, aluminum, or other metals.

-

Laser Power: Ensure the lens can handle the machine’s power rating. Exceeding the lens’s power limit may cause damage.

-

Focal Length: Shorter focal lengths provide higher precision for thin materials, while longer focal lengths are suitable for thick metal plates.

Conclusion

The fiber laser cutting machine lens is more than just an optical accessory—it is essential for precision, efficiency, and long-term machine reliability. Selecting the right lens and maintaining it properly ensures consistent cutting quality, reduces operating costs, and minimizes downtime.

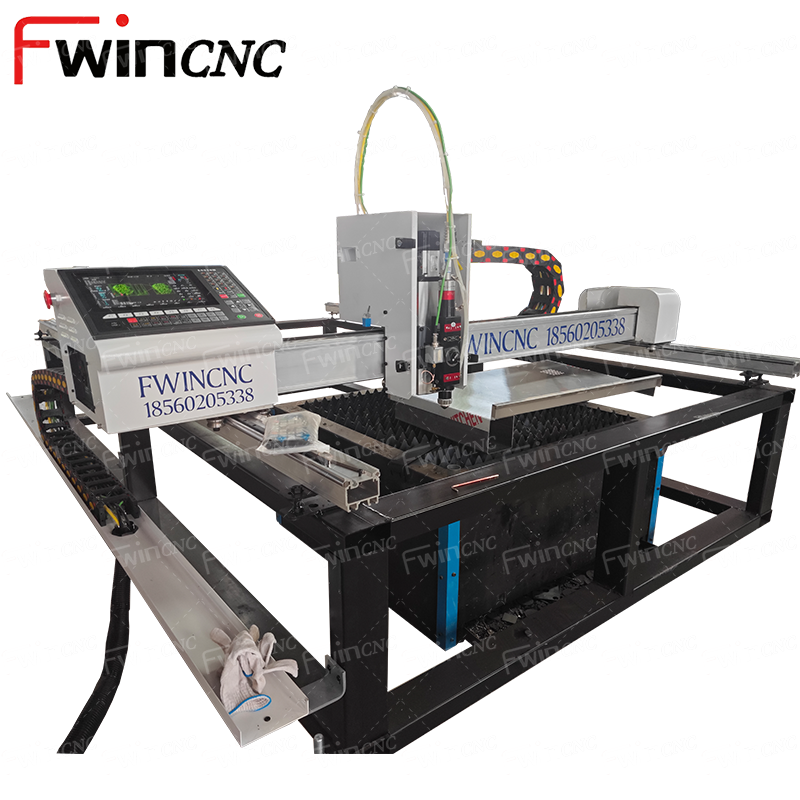

At FWINCNC, we provide high-quality fiber laser lenses suitable for various power levels and applications. Our lenses are designed for durability, precision, and ease of maintenance, helping metal fabrication professionals achieve superior cutting results every time.

Invest in premium fiber laser lenses to maximize your machine’s performance and ensure long-term reliability.