Plasma Bevel Head Cutting Machine for Pressure Vessel Dished Ends – Russia

Table of Contents

Delivering Reliable Bevel Cutting Solutions with Localized Service Support

Project Background: A Clear Requirement for Bevel Cutting

A Russian customer contacted FWINCNC with a specific requirement for a plasma bevel cutting solution designed for pressure vessel heads. The project demanded stable bevel accuracy, consistent cutting quality, and the ability to handle thick metal materials commonly used in industrial fabrication. Given the complexity of bevel cutting applications, the customer placed strong emphasis on machine capability, structural rigidity, and long-term reliability.

Technical Consultation: Matching the Right Solution to the Application

After receiving the inquiry, our engineering and sales teams worked closely with the customer to fully understand the production requirements, material specifications, and expected cutting results. Based on this analysis, we recommended a plasma bevel head cutting machine specifically configured for pressure vessel components, ensuring both cutting precision and operational stability.

Detailed technical discussions were conducted remotely, covering bevel angles, cutting thickness range, machine structure, and control system functionality. This stage helped the customer gain a comprehensive understanding of how the equipment would perform in real production conditions.

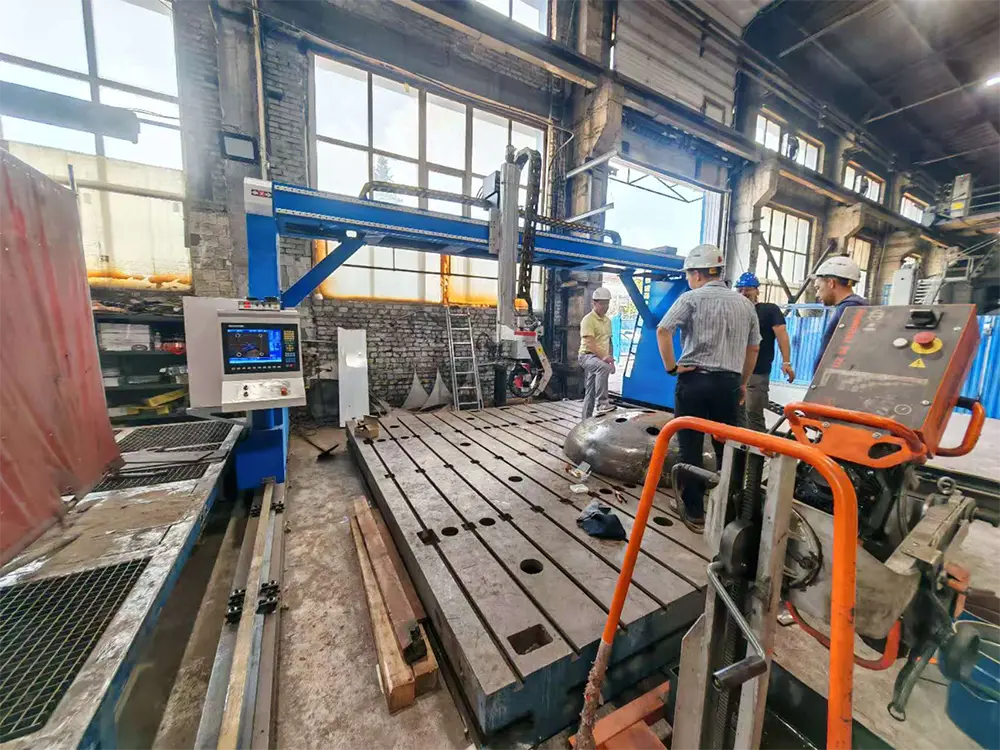

Factory Visit: On-Site Evaluation and Confidence Building

To further verify machine performance, the customer decided to visit our factory in China. During the on-site inspection, they observed live cutting demonstrations, evaluated bevel quality, and reviewed machine assembly standards and quality control processes. The visit allowed the customer to directly assess our manufacturing capability and confirm that the machine fully met their technical expectations.

After the factory inspection, the customer expressed strong confidence in both the machine quality and FWINCNC’s professional competence, leading to a final purchasing decision.

Order Confirmation and Production

Following the visit, the order for the plasma bevel head cutting machine was confirmed. The machine was manufactured according to the agreed technical specifications and underwent standard factory testing before shipment to ensure stable operation and consistent cutting accuracy.

Throughout the production process, our team maintained regular communication with the customer, providing updates and technical confirmations to ensure full transparency.

Installation and After-Sales Support: Beyond Language Barriers

After delivery, FWINCNC provided comprehensive after-sales support. Although the original operation manual was available in English, we recognized the importance of localized documentation for efficient operation. To support the customer’s team, we prepared a dedicated Russian-language manual covering machine installation, parameter setup, operation procedures, and maintenance guidelines.

In addition, our engineers provided full online technical support throughout the installation and commissioning process. From initial setup to final cutting tests, the customer received real-time guidance to ensure smooth and efficient machine startup.

Project Outcome: Stable Operation and Reliable Performance

With proper installation and professional support, the plasma bevel cutting machine was successfully put into operation at the customer’s facility. The machine delivered stable bevel angles, clean cutting edges, and consistent performance, fully meeting the production requirements for pressure vessel head fabrication.

This project not only demonstrated the technical capability of FWINCNC’s plasma bevel cutting solutions but also highlighted our commitment to customer-oriented service, localized support, and long-term reliability.