Plasma Cutting Machine Series

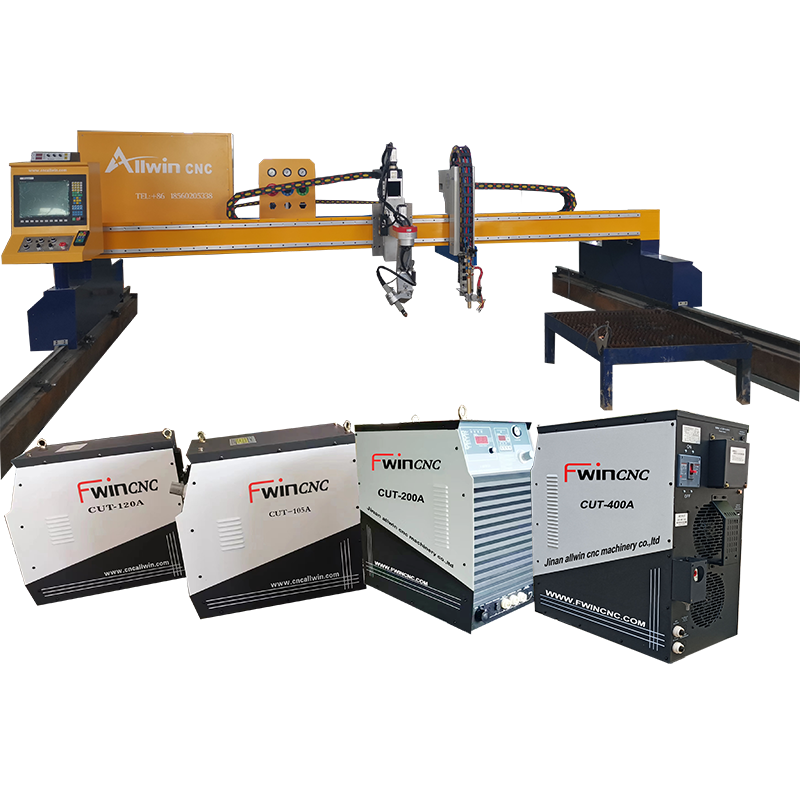

FWINCNC offers a complete range of CNC plasma cutting machines tailored for different production needs and budgets:

-

Portable Plasma Cutting Machine – lightweight, flexible, and easy to operate, ideal for on-site cutting tasks.

-

Gantry Plasma Cutting Machine – robust design for large-format sheet cutting with high stability and accuracy.

-

5-Axis Bevel Plasma Cutting Machine – specialized for bevel and edge preparation on pipes and plates.

-

Plasma Plate & Tube Integrated Machine – one system for both sheet and pipe cutting, improving efficiency.

-

Desktop Plasma Cutting Machine – compact and cost-effective, perfect for small workshops and precision work.

While most metal cutters require a lot of training and experience to use effectively, CNC plasma cutters are easier to use and do not require as much training to handle properly.This means that CNC plasma cutting machines can help minimize the overhead costs and downtime associated with training new employees.

While most metal cutters require a lot of training and experience to use effectively, CNC plasma cutters are easier to use and do not require as much training to handle properly.This means that CNC plasma cutting machines can help minimize the overhead costs and downtime associated with training new employees.

Plasma cutters are no longer only utilised in smaller-scale industrial businesses and for creating artistic pieces. They are now found in almost all intensive metal industries like the aerospace, automotive and defence industries. And its fast cut speed,powerful cutting strength makes the plasma cutting has more applications.

CNC plasma cutting is an extremely effective option for cutting both thin and thick metals. Materials includes steel, stainless steel, brass, copper, and aluminum, allowing you to use one machine to complete cuts for projects in different industries.

Minimize material waste through precise cutting, reducing the costs of raw materials. Meanwhile, the automation provided by CNC technology reduces labor requirements and the potential for human error, further driving down costs.

How to choose plasma cutting?

When people want to buy a plasma cutting machine,they would be confused how to choose a suitable one.As choosing the plasma cutting machine include many factors like cut thickness,working area,plasma power,the specific needs of your operation etc.

We Fwincnc produce different types of plasma cutter to meet customers’ various demands.Every type has its own featurers and price is different,you can take it into consideration before deciding to buy.Of course,FWINCNC can recommend the most suitable one upon your detail demands and budget.

Crossbow plasma cutter has a simple structure and an affordable price.

Working size like 1500mmx3000mm/1500mmx4000mm/1500mmx6000mm.

It is a better choice for customers with limited budgets and not very high precision requirements, as well as those with limited space,very friendly to new entrepreneurs.

Dual drive plasma cutter working size includes like 2300x3000mm/2300x6000mm.

For X axis, it is made of aluminum. Due to its material, the X-axis cannot be too long and the cutting head cannot be too heavy; otherwise, it will cause deformation of the X axis,for X axis ,the max effective cutting width is 3000mm,for Y axis can be extended without limit.It is suitable for cutting thick material like 20mm,30mm,apply industry like heavy-duty cutting shipbuilding, construction etc,and can meet high-speed, high-precision requirements.

The desktop plasma cutting machine has high cutting accuracy.

Although its cutting accuracy is slightly higher than that of other plasma pipe cutting machines, it cannot match the accuracy of laser cutting machines.Also it is very heavy and the working areas is limited bcz of container size. Therefore, this model has gradually withdrawn from the historical stage in recent years and has been gradually replaced by laser cutting machines.

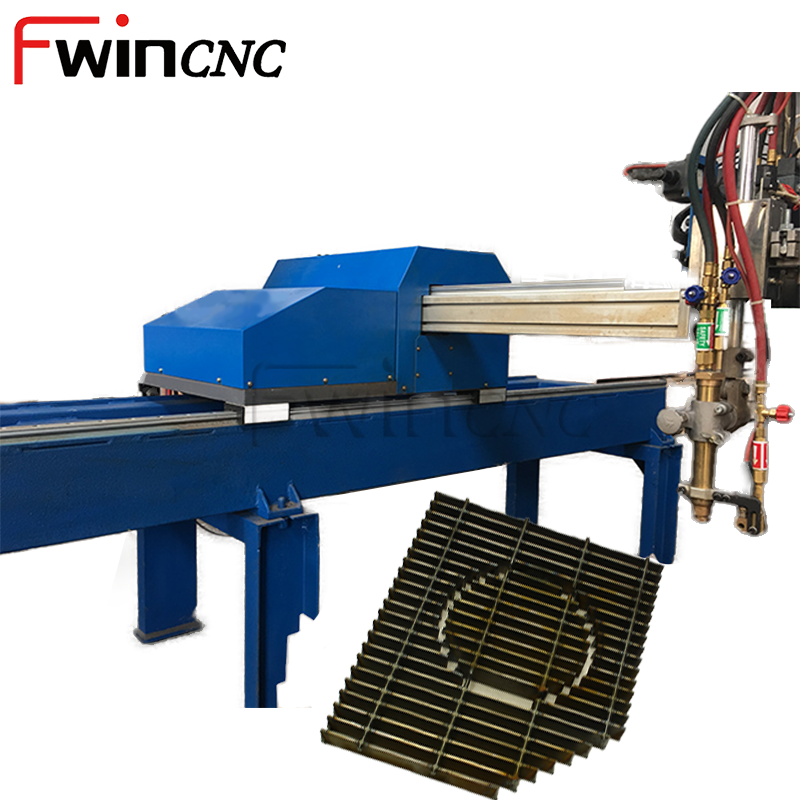

Gantry Plasma Cutting Machine includes bevel cutting and standard cutting types.

The bevel cutting machine features an additional axis for angled cutting (e.g., V-grooves, chamfers), and its control system is different from standard plasma cutters. So the price of a bevel-cutting plasma machine is a little higher than that of a conventional model.

The gantry type plasma cutting machine is mainly used for cutting large-format metal materials, with fast cutting speed and precision High, stable operation, small deformation, good cutting effect (smooth cut, no residue). The types of metal materials that can be cut include H-shaped steel, channel steel, angle steel, etc., suitable for large-scale construction machinery.Compared with portable plasma cutter,its cost is higher .The machine is suitable for mid-to-high-end customers.

The bevel cutting machine can cut bevels.

This bevel slope can be cut from 0 to 45 degrees. Bevel cutting is more convenient for welding,eliminating the need for secondary machining.After welding, the contact surface is larger, the welding effect is more firm, the service life is longer, and it is safer.It is Ideal for V-grooves, Y-grooves, and chamfering with smooth, slag-free edges.It is mainly used in industries that have bevel cutting requirements for plates, such as metal fabrication, shipbuilding, medical and heavy construction.

Plasma bevel dish head cutting machine is specifically designed for cutting curved metal covers (heads)

This machine can perform vertical cuts as well as bevel cuts (grooves, chamfers, etc.) on rounded metal heads. It is primarily used for cutting end caps (heads) and is widely applied in industries such as chemical, petroleum, and food processing for manufacturing reactors, storage tanks, and various vessels.

Why Choose FWIN Plasma cutting machine?

✅ Wide Cutting Capability – Handles stainless steel, carbon steel, aluminum, copper, and alloys with high efficiency.

✅ Flexible Configurations – Portable, gantry, desktop, and 5-axis bevel cutting machines for diverse needs.

✅ High Cost-Performance – Lower investment than laser cutting while delivering clean, reliable results.

✅ Durability & Low Maintenance – Robust design and optimized consumables extend machine lifespan.

✅ Global Support – 2-year warranty and 24/7 online technical assistance.

Plasma Cutting Machine Applications

1. Applied Materials

CNC plasma cutting machines are suitable for stainless steel, carbon steel, galvanized sheet, aluminum, copper, titanium, and other non-ferrous metals.

2. Application Industries

Widely used in shipbuilding, construction, petrochemical, power equipment, boiler manufacturing, heavy machinery, aerospace, automotive, and metal fabrication workshops.

FAQ

Plasma cutters are suitable for conductive metals such as carbon steel, stainless steel, galvanized steel, aluminum, copper, and alloys. For thicker sections, plasma cutting is often more cost-effective than laser cutting.

-

Portable – flexible, low-cost, ideal for on-site jobs.

-

Gantry – large-format cutting, high stability, suited for heavy industry.

-

Desktop – compact and precise, best for small workshops or sheet cutting.

Plasma cutting offers lower investment cost and can handle thicker plates efficiently, though with slightly less precision than fiber laser. Laser is preferred for high-precision thin sheet cutting, while plasma is widely used for general metal fabrication and budget-friendly large-scale cutting.