High Precision & Clean Edge Solutions

Advanced Cutting Technologies for Superior Accuracy and Surface Quality

Precision cutting is no longer a premium option—it is a production necessity. From tight-tolerance components to visually demanding finished parts, manufacturers increasingly require clean edges, consistent accuracy, and minimal post-processing.

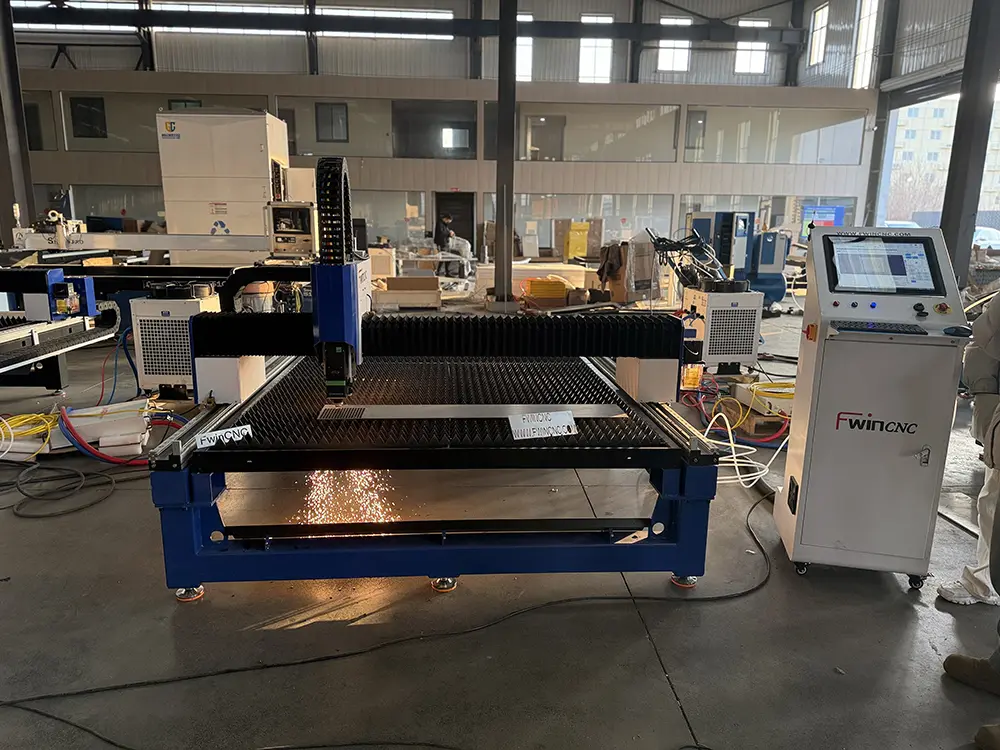

FWINCNC’s High Precision & Clean Edge Solutions are designed for customers who prioritize cutting quality, dimensional stability, and refined surface results. These solutions combine advanced laser and plasma technologies with rigid mechanical structures and optimized control systems, helping users achieve professional-grade output across a wide range of metal fabrication applications.

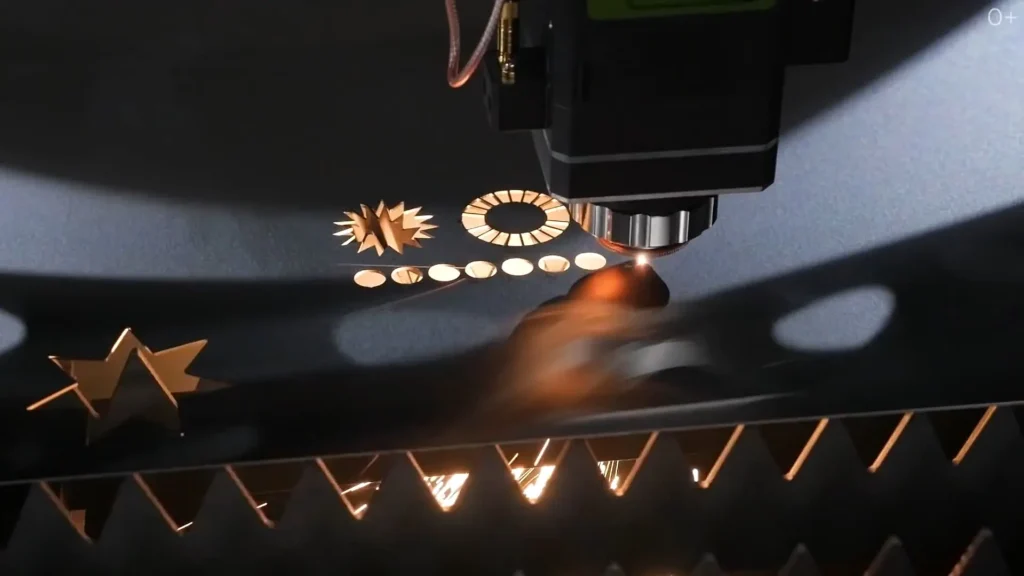

Laser Cutting Solutions for Fine Detail and Mirror-Like Edges

Fiber laser cutting remains the preferred choice for applications where edge smoothness, dimensional precision, and repeatability are critical. FWINCNC provides laser cutting machines that deliver clean kerfs, sharp contours, and excellent perpendicularity across thin to medium-thickness metals.

This solution includes desktop laser cutting machines, portable laser cutters, detachable laser cutting machines, and high-power gantry or rail-type laser systems. These machines are ideal for stainless steel, carbon steel, aluminum, and non-ferrous materials where high visual quality and tight tolerances are required.

Precision Tube and Profile Cutting for Complex Geometries

High-accuracy tube cutting demands precise rotary control, stable clamping, and synchronized motion. FWINCNC’s laser and plasma tube cutting solutions are engineered to handle complex pipe geometries while maintaining consistent cut quality.

Laser tube cutting machines and plasma pipe cutting systems support round, square, rectangular, and custom profiles, enabling clean slots, holes, bevels, and intersecting cuts. These solutions significantly reduce secondary machining and improve assembly accuracy in downstream processes.

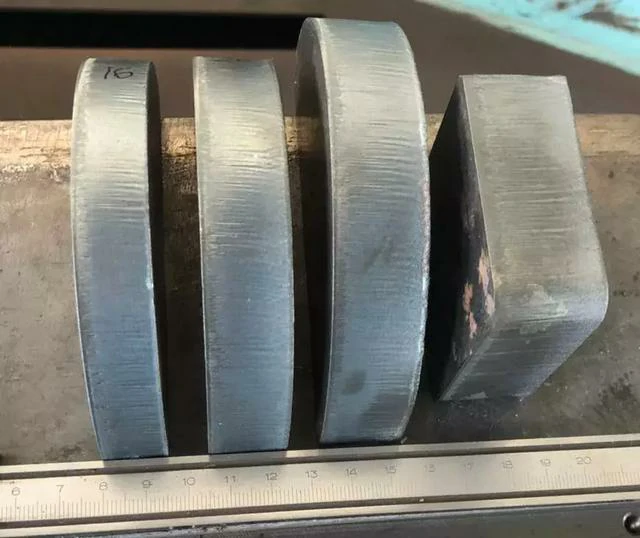

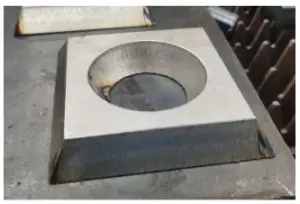

Bevel and Angle Cutting Solutions for Welding-Ready Edges

For pressure vessels, structural components, and heavy fabrication, bevel accuracy directly impacts welding quality. FWINCNC offers plasma bevel cutting machines and plasma bevel pipe cutting systems designed to produce accurate angles, uniform chamfers, and consistent groove profiles.

These solutions ensure precise V, Y, and K bevels, reducing manual grinding and improving welding efficiency. Stable motion control and optimized torch positioning allow users to achieve clean bevel surfaces even on thick materials.

Clean Welding and Surface Preparation with Laser Technology

High precision is not limited to cutting alone. FWINCNC’s laser welding and laser cleaning systems provide refined solutions for joining and surface treatment tasks where appearance and accuracy matter.

Laser welding machines deliver narrow weld seams, minimal heat distortion, and clean weld aesthetics. Laser cleaning systems remove rust, paint, and contaminants without damaging the base material, making them ideal for pre-weld preparation and high-end surface treatment.

Precision That Translates into Productivity

FWINCNC’s High Precision & Clean Edge Solutions are engineered to help customers reduce rework, shorten production cycles, and elevate finished product quality. By combining accurate motion systems, advanced cutting technologies, and application-focused design, these solutions enable manufacturers to meet higher standards with confidence.

Whether producing detailed metal parts, complex pipe structures, or weld-ready components, FWINCNC delivers precision-focused equipment that supports long-term manufacturing excellence.