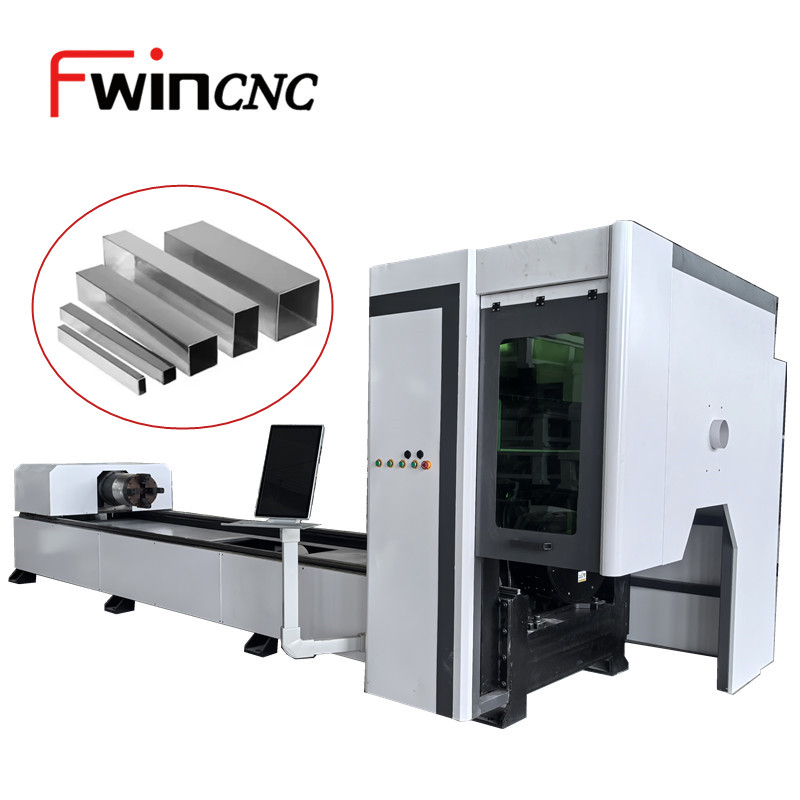

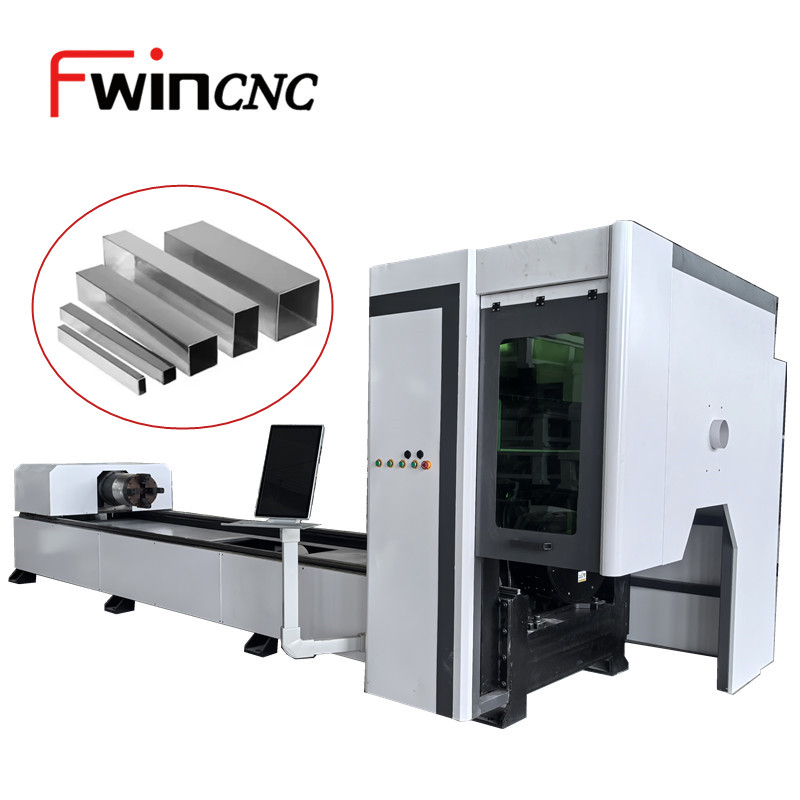

Closed Type Heavy Duty Metal Pipe Laser Cutting Machine

The Closed Type Heavy Duty Metal Pipe Laser Cutting Machine delivers precise, efficient cutting for a wide range of metal pipes. Its fully enclosed design ensures operator safety and reduces dust and noise. Built with a sturdy frame and high-power fiber laser, it handles thick and complex pipes with minimal distortion. Ideal for industrial use, it combines automation and durability to boost productivity while maintaining top-quality results.

Features of Closed Type Heavy Duty Metal Pipe Laser Cutting Machine

- Fully enclosed structure for enhanced safety by containing laser radiation and debris

- High-power fiber laser source for fast and precise cutting

- Rigid frame and advanced servo motors ensure stable operation and consistent quality

- Capable of cutting thick and complex metal pipes with minimal heat distortion

- Integrated dust extraction and filtration system to maintain cleanliness and protect components

- Automated loading and unloading to improve efficiency and reduce manual labor

- Noise reduction due to closed design, creating a quieter working environment

- Supports various metal types such as stainless steel, carbon steel, and aluminum

- Suitable for heavy-duty industrial applications requiring precision and durability

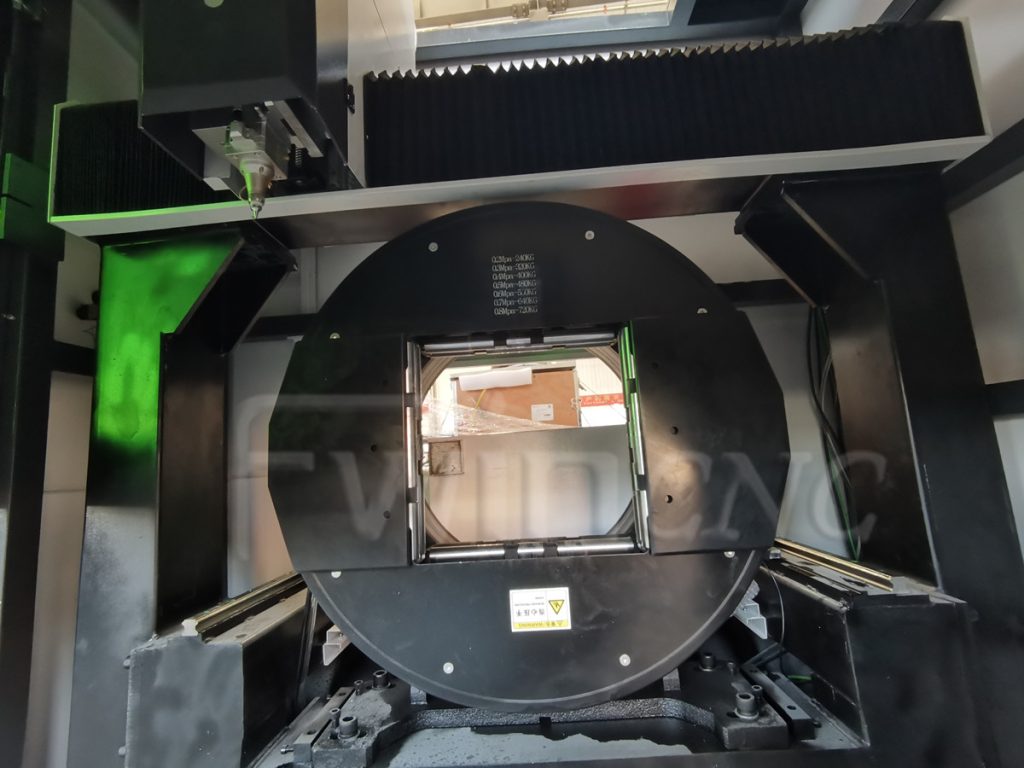

High-precision sealed pneumatic chuck

1.The integrated high-rigidity chuck provides safe and reliable clamping, avoiding vibration during cutting. The built-in gear is dust-proof, has low noise and a large clamping range, which can meet the needs of cutting various pipes. Double-sided pneumatic clamp design, automatic center adjustment,

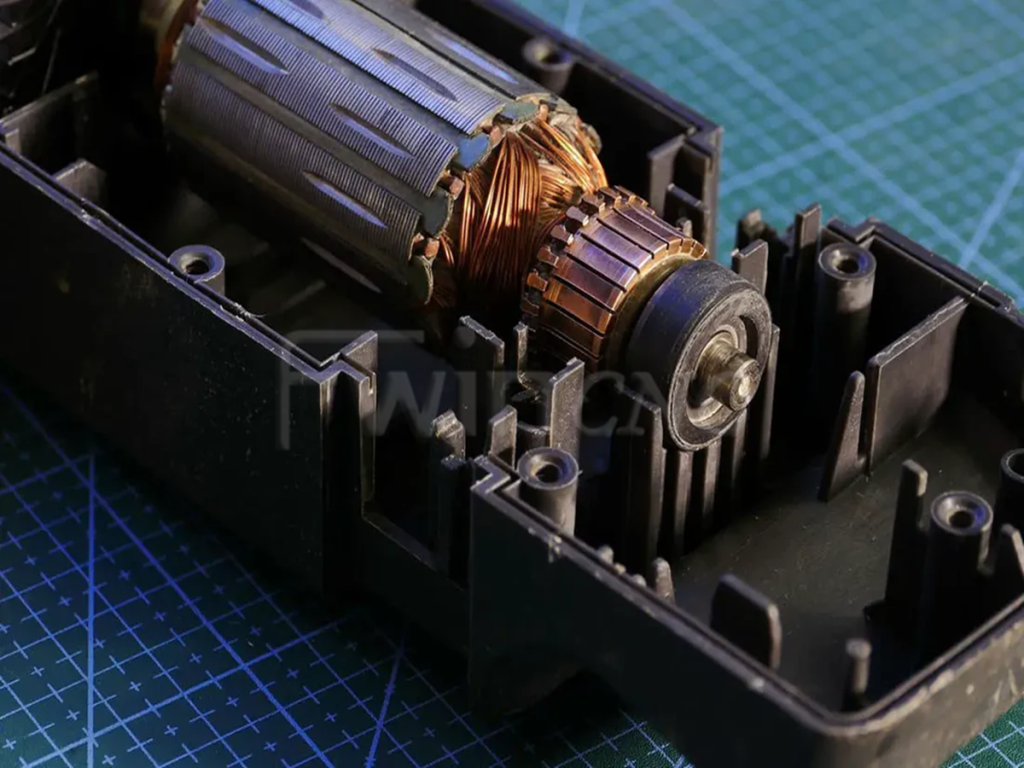

2.Servo Motors

We work with renowned Chinese brands whose products have been proven in the market for many years. They offer adjustable, automatic focus adjustment, freeing your hand and Optimal cutting results for metals of varying thicknesses

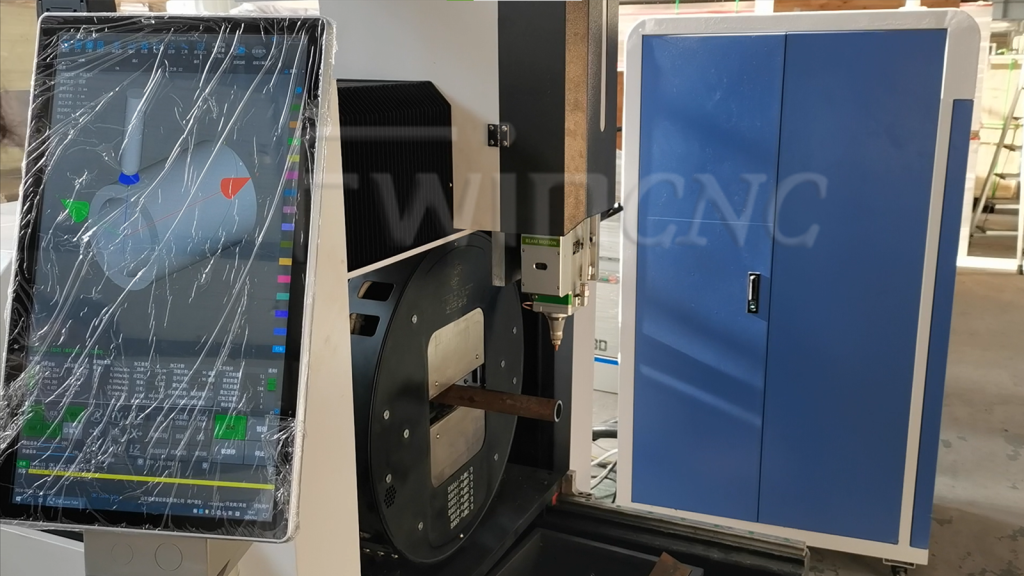

3.Laser control system

CypCut is a popular and effective control system for fiber laser cutting machines used in metal fabrication. It is a single, integrated software that combines CAD, CAM, and control functions, offering a range of features such as graphics processing, parameter setting, process customization, parts nesting, and path planning. CypCut is known for its high precision, stability, and ease of use, making it a top choice for industrial laser cutting of various metal sheet and pipe materials.

| Product Name | Closed Pipe Laser Cutting Machine(with protective cover) |

| Power of Generator | 1000-6000W |

| Working size | Round pipe diameter: Ф16-Ф500mm Square pipe diagonal: Ф16-Ф300mmRectangular: long side ≤250mmMaximum cutting length:12m Minimum cutting length: 2m Shortest remaining material:80mm |

| Packing dimension | 2250mmx3700mmx1700mm |

| Weight for machine | 2700KGS |

| Laser Source | World Famous Fiber Laser Source (Raycus/Max/ IPG) |

| Laser head | Swiss RAYTOOLS BM111 with autofocus(for other option) |

| software | Cypcut software |

| controller system | Professional FSCUT 3000 |

|

Motor and driver |

servomotors X,Y 850W+400W Z axis |

| rotary axis use 3000w servo motor | |

| Reducer | Japan SHlMPO reducer |

| Water chiller | HANLl brand with Dualtemperature,dual control |

| Rack and pinion | Taiwan brand T-WlN rack and pinion |

| Gantry type | Aluminum cast gantry |

| Transmission Method | High Precision Gear Transmission |

| Transmission type | Gear rack transmission system |

| Maximum ldle Speed | 90m/min |

| Repeated Positioning Degree | ≤±0.02mm |

| Focus Method | Dynamic Auto-Focusing System |

| Working voltage | 380v50Hz+10% |

A closed pipe laser cutter is a precision machine designed to cut pipes and pipes with high accuracy using laser technology within a controlled, enclosed environment. This type of cutter offers several advantages, such as enhanced safety, reduced contamination, and consistent cutting quality.

- Industrial Manufacturing:

Closed type pipe laser cutting machines are widely used in industries that require precise pipe and pipe fabrication, such as automotive, aerospace, and heavy machinery manufacturing. They enable clean and accurate cuts for components like exhaust systems, hydraulic lines, and structural frames, ensuring high-quality assembly and reducing material waste. - Construction and Engineering:

In construction, pipe laser cutting machines are essential for producing pipes and structural tubing used in frameworks, scaffolding, and pipelines. The precise cutting helps maintain structural integrity and simplifies the installation process. - Oil and Gas Industry:

For the oil and gas sector, closed-type pipe laser cutters facilitate the fabrication of pipelines and tubular components that must meet stringent safety and durability standards. The enclosed system ensures consistent quality, reducing the risk of defects that could lead to leaks or failures. - Medical Equipment Manufacturing:

The medical industry uses these cutters to manufacture precise and sterile tubular components for devices such as surgical instruments, implants, and diagnostic equipment. The enclosed cutting environment helps maintain cleanliness and prevents contamination. - Custom Fabrication and Prototyping:

Closed type pipe laser cutting machine is also valuable for custom fabrication shops and prototyping, where intricate and varied pipe designs are needed quickly and accurately.

In summary, the closed type pipe laser cutting machine is essential in applications demanding high precision, safety, and cleanliness, making it a vital tool across various industrial sectors.

Fully enclosed laser pipe cutting machines represent an advanced technological solution designed to cut pipes and pipes with precision and efficiency within a controlled, closed environment. This design brings several benefits, but it also comes with some limitations. Below is a balanced overview of their advantages and disadvantages.

Advantages

- Enhanced Safety

The fully enclosed design significantly improves operator safety by containing the laser beam within the machine’s housing. This reduces exposure to harmful laser radiation, sparks, and debris generated during cutting, protecting workers and minimizing the risk of accidents. - Improved Cutting Quality

By isolating the cutting process inside a sealed chamber, environmental factors such as dust, airflow, and contaminants are minimized. This stable environment contributes to consistent, high-quality cuts with clean edges and minimal thermal distortion, which is crucial for maintaining the integrity of complex pipe geometries. - Noise Reduction

The enclosure acts as a sound barrier, decreasing the noise level generated during cutting. This creates a more comfortable working environment, especially important in manufacturing settings where multiple machines operate simultaneously. - Dust and Fume Control

Laser cutting produces fumes and fine particles, especially when working with coated or treated materials. A fully enclosed system often integrates ventilation and filtration units, capturing harmful emissions and preventing workplace pollution, which helps meet environmental and safety regulations. - Automation and Integration

Many fully enclosed laser pipe cutters are designed for seamless integration with automated loading, unloading, and robotic systems. This increases production efficiency, reduces manual labor, and allows for continuous operation with minimal downtime. - Protection of Optical Components

The closed environment protects delicate laser optics from contamination by dust or metal particles, reducing maintenance frequency and prolonging the lifespan of critical components.

Disadvantages

- Higher Initial Investment

Fully enclosed laser pipe cutting machines generally come with a higher upfront cost compared to open or semi-enclosed alternatives. The advanced safety features, filtration systems, and automation increase the machine’s complexity and price, which may be a barrier for smaller workshops or startups. - Maintenance Complexity

While the enclosure protects optics and improves cutting quality, it also requires specialized maintenance. Filters, ventilation units, and enclosure seals need regular inspection and replacement, adding to operational costs and requiring trained personnel. - Limited Accessibility

The sealed design can restrict quick access to the work area, making manual adjustments or intervention more cumbersome. This can slow down troubleshooting or manual operations, potentially impacting production flexibility. - Size and Space Requirements

Fully enclosed machines are often larger and heavier due to their protective casing and integrated systems. This demands more floor space and may require reinforced foundations, which could be challenging in facilities with limited room. - Heat Management Challenges

The enclosed environment traps heat generated during cutting. Without proper cooling systems, this can affect machine performance and component longevity. Effective thermal management solutions are essential but add to complexity and cost. - Material Limitations

Some materials may require open cutting environments due to fumes or debris characteristics that challenge enclosed filtration systems. While most metals and pipes are suitable, certain composites or coated pipes might need alternative cutting methods.

Fortunately , we provide open type pipe laser cutting machines, and we also offer economical and portable laser pipe cutting machines, portable plamsa pipe cutting machines.

Related News

1. Prevention of Laser Condensation Laser cutting machinery requires water cooling for both laser and optical components. Given the high […]