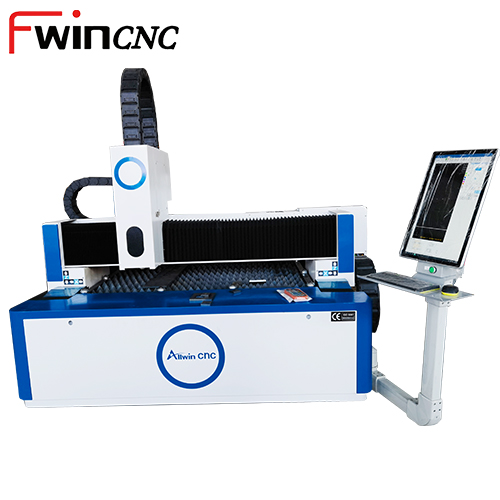

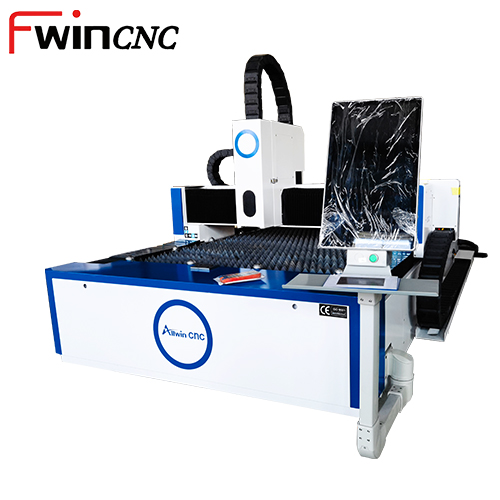

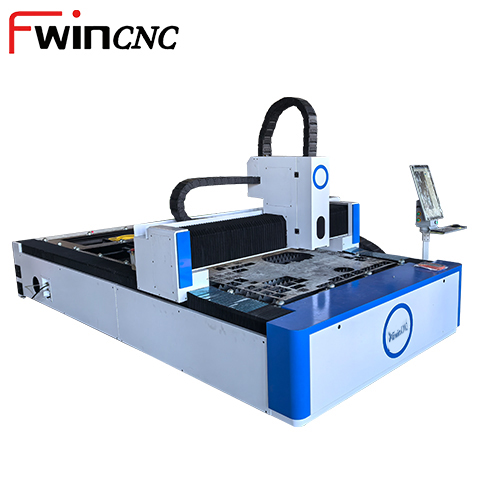

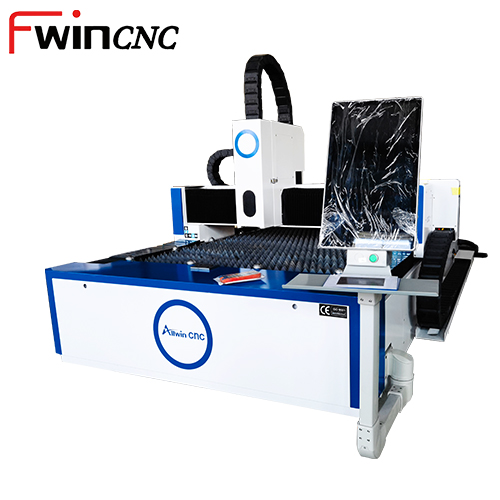

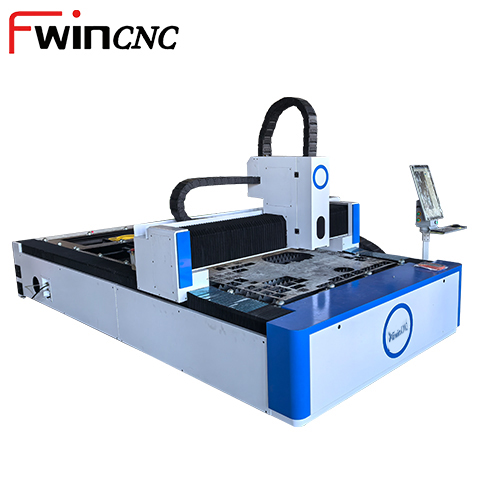

Fiber Laser Cutting Mchine for Metal

Our fiber laser cutter features patented design, precise cutting, fast speed, smooth seams, low energy use—ideal for industrial production.

-

Sturdy Welding Bed – Made entirely from 8mm plate with mortise-and-tenon structure for high stability.

-

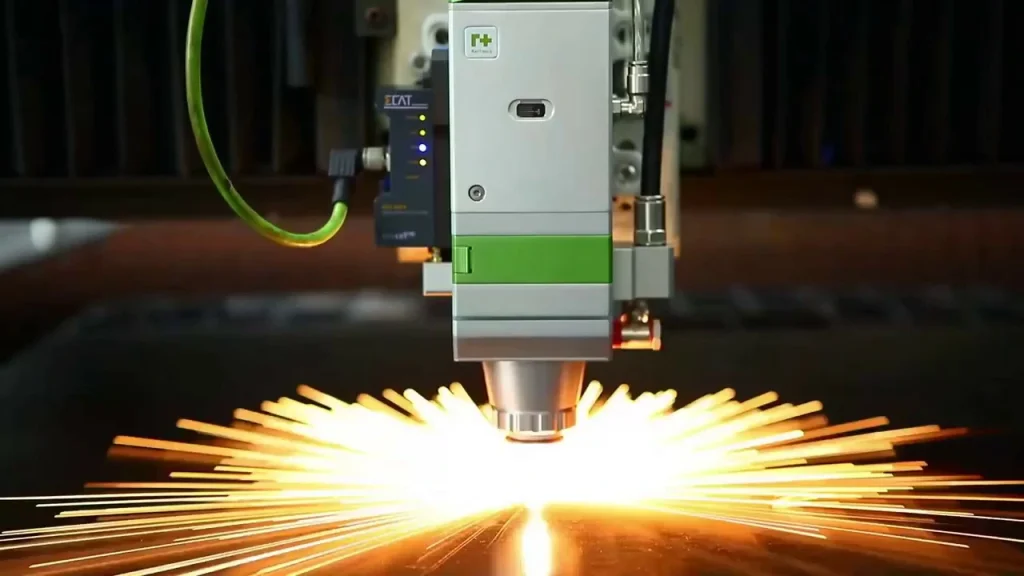

High-Quality Laser System – Equipped with RAYCUS/MAX fiber laser and industrial water chiller.

-

Optional Partition Dust Removal – Keeps working area clean and prolongs machine life.

-

Optional Anti-Burn Components – Protects key parts and enhances safety.

-

Flexible Electric Box – Front electric box standard; independent box available as upgrade.

-

Enhanced Airflow – 200 air ducts on both sides improve dust and smoke removal efficiency.

CNC Fiber Laser Cutting Machine – Product Details

FEATURES FOR FIBER LASER CUTTING MACHINE

-

Energy Efficient – Laser power consumption is only 0.5–1.5 kW/h, reducing operational costs.

-

High-Quality Laser Source – Chinese top-brand fiber lasers (JPT, RAYCUS, MAX, IPG) deliver high performance, stability, and over 100,000 hours service life with minimal maintenance. Thin plate cutting speed exceeds 10 m/min.

-

Automatic Height Adjustment – Laser head with automatic height sensor ensures precise cutting on uneven surfaces.

-

Precision Motion System – Imported ball screw and linear guide rail provide smooth, accurate movement for consistent cutting quality.

-

User-Friendly CNC Software – Fast programming and intuitive interface optimize productivity and pattern execution.

-

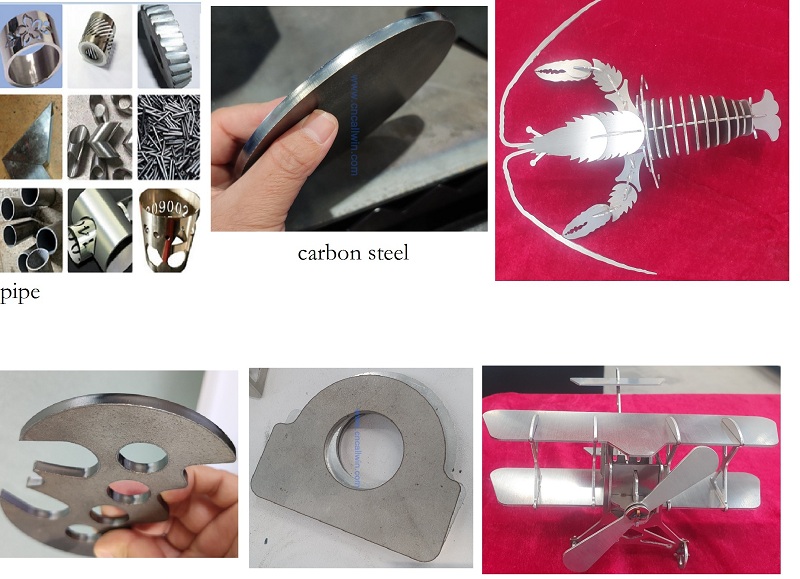

Material Compatibility – Cuts iron, aluminum, carbon steel, stainless steel, copper, and other metal sheets effortlessly.

-

Customizable Options – Choose laser power (500–12000W), rotary axis, exchange table, full cover, and more to match specific requirements.

-

Flexible Working Area – Standard 1500×3000mm, customizable to suit different project sizes.

-

Guided Selection for New Users – Provide metal type, thickness, and desired working area for the most suitable machine configuration.

Technical parameters of fiber laser cutting machine

| No. | machine model:ALLWIN-3015 2000W/6000W/120000W | ||||

| 1 | Max working area | 1500mmx3000mm | |||

| 2 | Packing dimension | 2200mmx3700mmx1700mm | |||

| 3 | Laser source | 2KWW/3KW/6KW/12KW/ RAYCUS fiber laser | |||

| 4 | Laser head | Swiss RAYTOOLS with auto focus | |||

| 5 | Software | Professional Cypcut software | |||

| 6 | Motor and driver | Japanese servo motors 850W | |||

| 7 | Reducer | Japan reducer | |||

| 8 | Water chiller | Industrial water chiller with Dual temperature,dual control | |||

| 9 | Rack and pinion | Taiwan brand rack and pinion | |||

| 10 | Guild rails | HIWIN GUILDER RAIL | |||

| 11 | Exhaust fan | Blower Exhaust fan | |||

| 12 | motor and driver | Japanese YASKAWA servo motors 850W | |||

| 13 | Air compressor | YES | |||

| 14 | voltage stabilizer | YES | |||

| 15 | Accessories included | RAYCUS/MAX FIBER LASER SOURCE 2KW/3KW/6KW | |||

| 1 SET RAYTOOLS LASER HEAD(AUTOMATIC FOCUS) | |||||

| 1 SET WATER CHILLER | |||||

| CYPCUT SOFTWARE | |||||

| INDUSTRIAL COMPUTER | |||||

| FAN | |||||

| LASER PROTECTION GLASSES | |||||

| FIBER LASER CUTTING BED | |||||

Laser Cutting Machine Applications

Laser cutting machines offer significant advantages over traditional mechanical processing: high precision, minimal deformation, energy efficiency, automation, no tool wear, and customizable shapes. These benefits make them widely applicable across industries.

1) Kitchenware Industry

High precision and fast cutting improve efficiency, reduce mold costs, and enable customized product designs.

2) Automotive Industry

Batch processing of precision parts ensures safety, high accuracy, burr-free edges, and one-time molding.

3) Fitness Equipment Industry

Flexible cutting for various shapes and specifications, smooth and burr-free surfaces without secondary processing.

4) Advertising & Signage Industry

High-precision cutting of metal letters eliminates rework, improves efficiency, and reduces corporate costs.

5) Sheet Metal Processing

High flexibility and fast cutting speed make fiber laser machines the preferred choice for modern sheet metal manufacturing.

6) Chassis & Cabinet Industry

Efficient cutting of thin plates for power distribution and file cabinets, supporting double-layer cutting for specific plates.

7) Agricultural Machinery Industry

Advanced laser processing reduces production costs, increases efficiency, and supports diversification and specialization.

8) Shipbuilding Industry

Precision cutting of marine steel plates with smooth surfaces, minimal thermal deformation, and accurate curves—ready for direct welding.

What is a Fiber Laser Cutting Machine?

A fiber laser cutting machine is a CNC system designed to cut various metal materials—including sheet metal, metal profiles, and tubes—efficiently and precisely, making it ideal for industrial metal fabrication.

It handles both 2D and 3D cutting projects on materials such as hot rolled steel, cold rolled steel, stainless steel, and carbon steel. Key components include the machine frame, fiber laser generator, reflector path, cutting head, industrial chiller, control panel, and CNC system, all engineered for high precision, smooth cuts, and reliable long-term performance.

How Fiber Laser Cutting Machines Work

A fiber laser cutting machine focuses a laser beam into an extremely small spot—often less than 0.1 mm in diameter—achieving a high power density that rapidly vaporizes the material at the focal point. The precise linear movement of the beam relative to the material forms a narrow cutting seam (≈0.1 mm) with minimal thermal impact and negligible deformation.

Auxiliary gases enhance cutting efficiency and quality:

-

Oxygen for steel: supports exothermic reactions, oxidizes molten metal, and blows away slag.

-

Nitrogen for high-precision metals: prevents oxidation and ensures clean, smooth edges.

Fiber laser cutting can process most metals, regardless of hardness, without deformation. Highly reflective or thermally conductive materials—such as gold, silver, copper, and aluminum alloys—are more challenging but can sometimes be cut with pulsed lasers to increase absorption and achieve precision cutting.

What is fiber metal laser cutting machine used for?

A fiber metal laser cutting machine concentrates laser energy into a high-density beam to precisely cut metal. The laser rapidly heats the material until it vaporizes, while high-pressure gas removes molten metal, resulting in clean, accurate cuts.

Unlike traditional machining, this process allows minimal thermal impact and deformation, making it ideal for industrial applications such as sheet metal fabrication, automotive parts, kitchenware, signage, and precision engineering.

The laser beam is emitted from a fiber laser generator, focused onto the workpiece via a reflector and optical path, creating a high-power-density spot that moves with the material to produce narrow, precise seams efficiently and reliably.

Fiber Laser Cutting Machine – Precision & Versatility

Our fiber laser cutting machine delivers high-precision, clean cuts for metal fabrication, automotive, aerospace, kitchenware, electronics, and signage.

It handles carbon steel, stainless steel, aluminum, copper, brass, titanium, and alloys, making it ideal for industrial manufacturing, small businesses, and creative projects. Boost productivity and reduce material waste—request a free quote today!

Transform Your Metal Cutting Process with FWIN CNC Fiber Laser

Our fiber laser cutting machine delivers high precision, fast cutting, smooth edges, and energy efficiency, enabling you to boost productivity and reduce operational costs. Compatible with a wide range of metals—including stainless steel, aluminum, carbon steel, and copper—it is ideal for industries such as automotive, kitchenware, sheet metal, and signage.

With customizable options like rotary axis, exchange working table, full cover, and laser power from 500W to 12kW, you get a machine tailored to your production needs. Request a free quote today to optimize your manufacturing line and gain a competitive edge.

Related Products

Related News

Investing in a laser cutting machine is a significant step toward enhancing your manufacturing capabilities, improving precision, and boosting productivity. […]

FWINCNC has released an enhanced generation of its Dismountable Laser Metal Cutting Machine, engineered for manufacturers that require high-precision cutting […]

The fiber laser cutting machine lens is a critical component in modern laser metal fabrication. It focuses the laser beam […]

What is laser ceramic ring? The ceramic ring is a commonly used accessory of laser cutting machine, the laser ceramic […]

Laser cutting machines are a valuable asset for many industries Laser cutting machine is a valuable asset for many […]

In recent years, the advent of portable laser cutting machines has significantly transformed the landscape of precision cutting in various […]

1. Prevention of Laser Condensation Laser cutting machinery requires water cooling for both laser and optical components. Given the high […]

The application of laser technology has emerged as a game-changer in the manufacturing processes of automobiles The automotive industry has […]