Laser Welding vs Traditional Welding Methods

Traditional welding methods such as resistance welding or arc welding rely on direct contact and higher heat input. These processes can cause excessive thermal stress, inconsistent weld quality, and potential damage to sensitive battery materials. Post-weld cleaning and rework are often required, increasing labor and production time.

Laser welding, by contrast, uses a concentrated beam with precise control over heat input. The heat-affected zone is smaller, reducing the risk of deformation and improving joint consistency. Weld quality is more uniform, and the process is easier to automate. This results in higher production efficiency, better product reliability, and lower long-term operating costs.

For lithium batteries and energy storage systems, where safety and consistency are essential, laser welding provides a clear technological advantage.

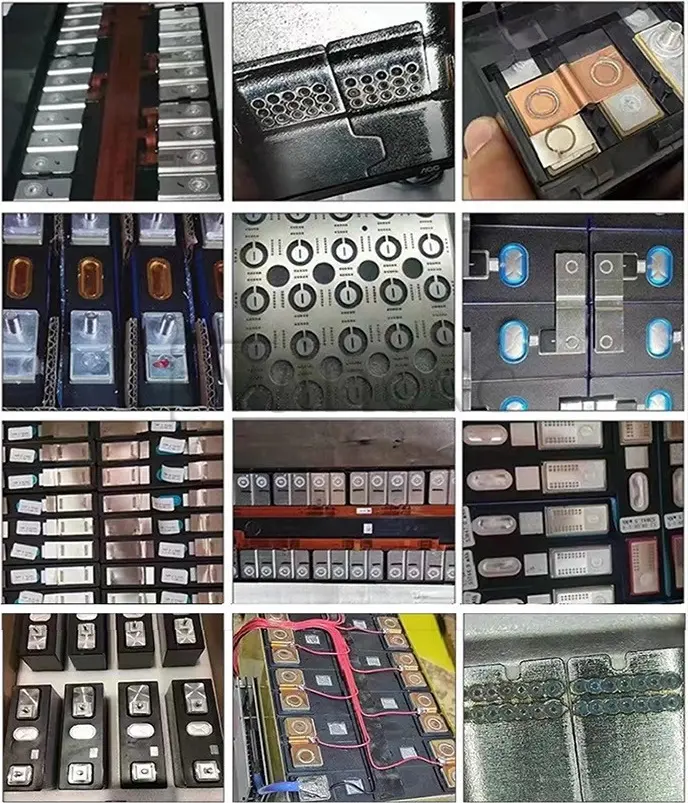

Why Choose Our Laser Lithium Battery Welding Machine

We focus on delivering practical and reliable laser welding solutions tailored to battery and energy storage applications. Each machine is designed for stable performance, long service life, and consistent welding results. The five-in-one configuration helps customers simplify production layouts while improving efficiency.

Our machines are tested for welding stability and process reliability before delivery. We offer flexible configurations, competitive pricing, and professional technical support to ensure smooth integration into your production line. By choosing our solution, customers gain a dependable welding system that supports product quality and long-term manufacturing goals.