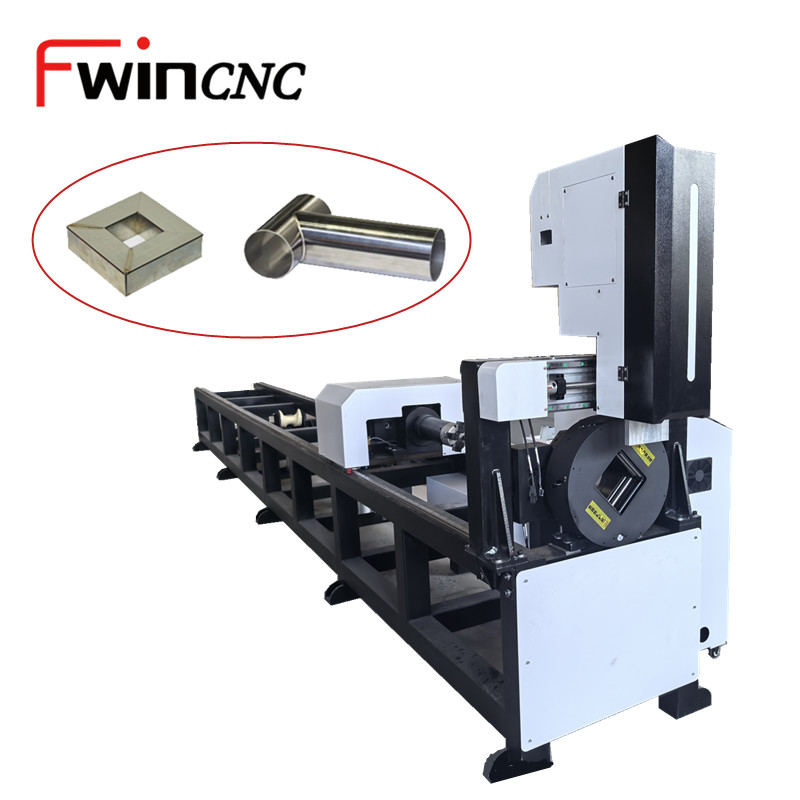

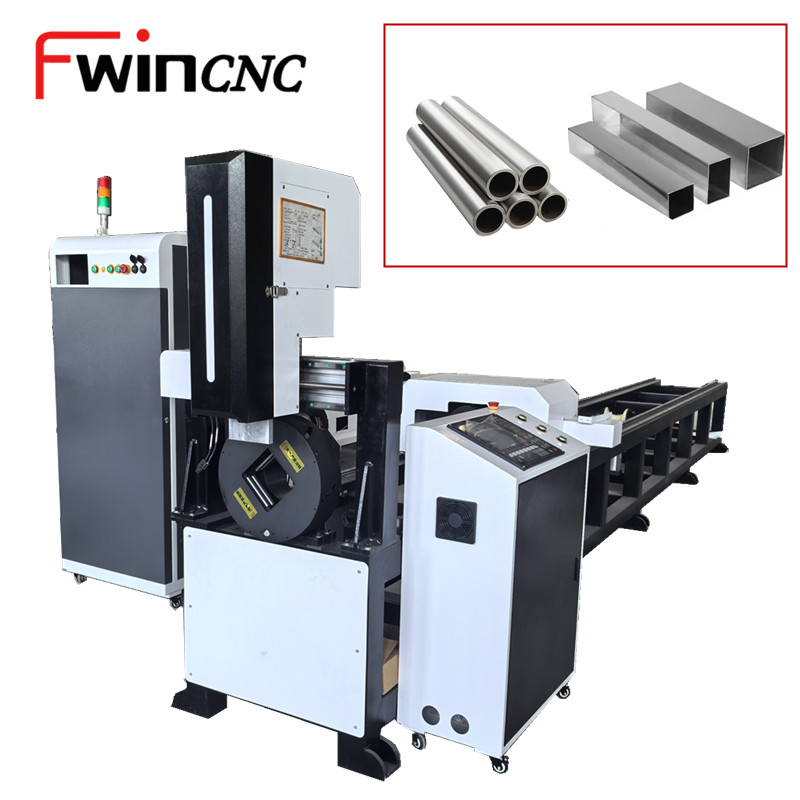

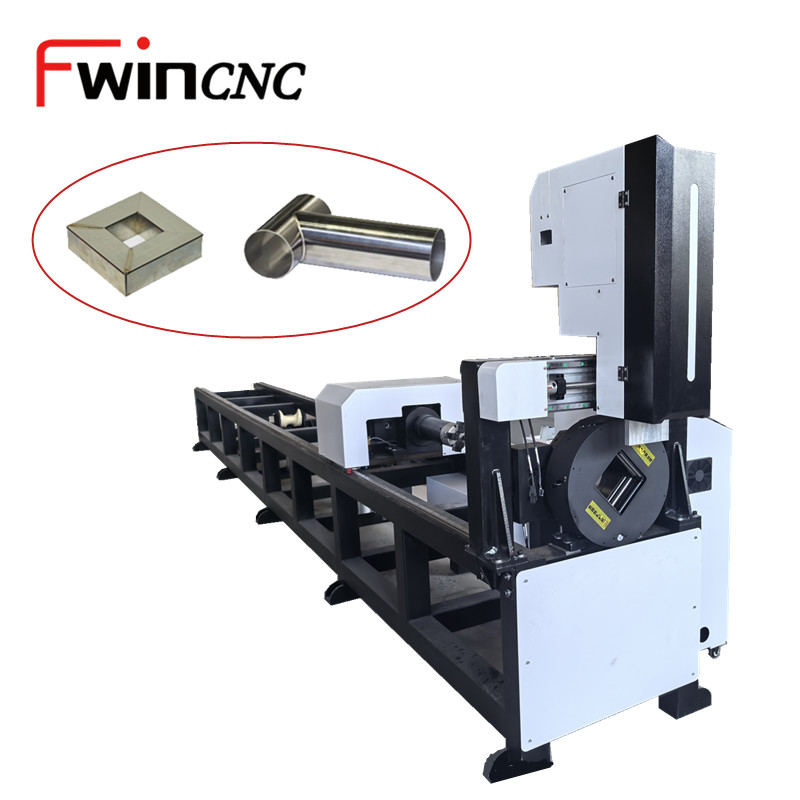

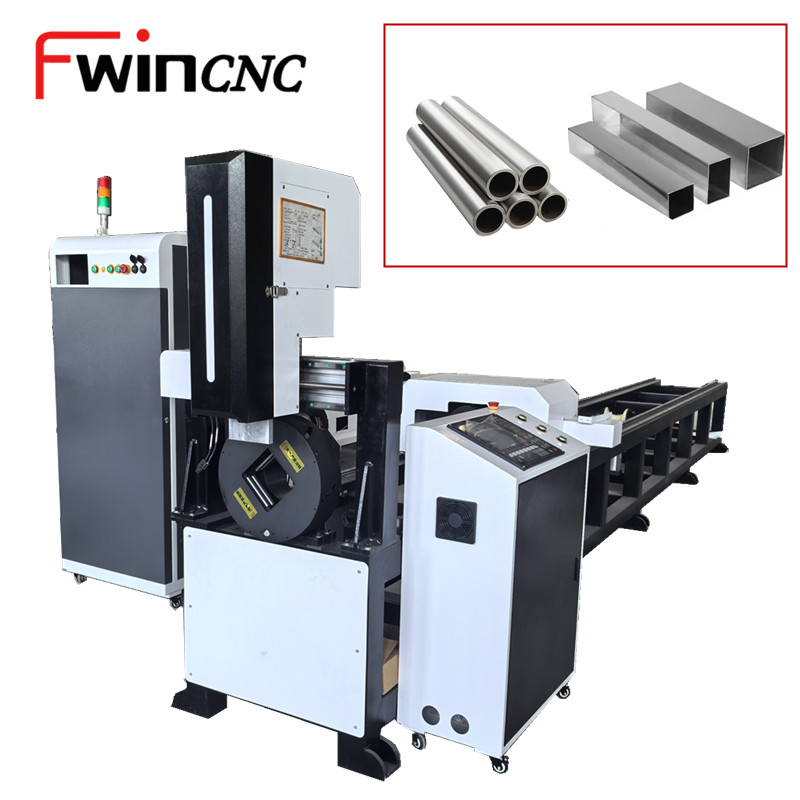

Laser Pipe Cutting Machine with Pneumatic Chuck Professional

Professional pneumatic chuck laser pipe cutting machine for precise square and round tube cutting in industrial applications.

- Pneumatic chuck for secure and rapid clamping of tubes.

- High-precision laser cutting for accurate square and round tube profiles.

- Automated operation reduces labor costs and increases efficiency.

- Versatile application for various tube materials and sizes.

- User-friendly interface with easy setup and maintenance.

Details of Pneumatic Chuck Laser Pipe Cutting Machine

The Pneumatic Chuck Professional Laser Square Round Pipe Cutting Machine is designed for high-performance pipe processing. With its advanced pneumatic chuck system, it ensures stable clamping during cutting, minimizing vibrations and enhancing accuracy. The laser cutting technology provides clean cuts with minimal burr, suitable for both square and round pipes. This machine offers significant value to manufacturers by reducing material waste, increasing production speed, and lowering operational costs. Key features include automated control for seamless operation and versatile compatibility with various metals.

Parameter of Pneumatic Chuck Laser Pipe Cutting Machine

| Chuck type | Pneumatic chuck |

| Pipe cross-sections | Round/Square/Rectangular |

| Round pipe | Φ6-Φ120mm |

| Square pipe | Φ6-Φ115mm |

| Rectangular pipe | Long side ≤ 115mm |

| Maximum pipe length | 6m |

| Maximum blanking length | 3m |

| Minimum excess material | 80mm |

| Approximate dimensions | 8×1.5×1.6m |

| Laser generator | MAX 1500W |

| Laser head | Raytools BM110 automactic focus |

| Controller system | Dedicated laser cutting system |

| Bed Stucture | Welded pipe beed |

| Guide | China brand 20 guide |

| Rack | YYC rack Automatic lubrication function |

| Servo motor and drive | Inovance 750W bus servo motor |

| Reducer | Japan Shinpo Reducer |

| Water Chiller | S&A water chiller |

Extensive Application of Pneumatic Chuck Laser Square Round Pipe Cutting Machine

The Pneumatic Chuck Professional Laser Square Round Pipe Cutting Machine is extensively applied across multiple industries due to its precision and efficiency.

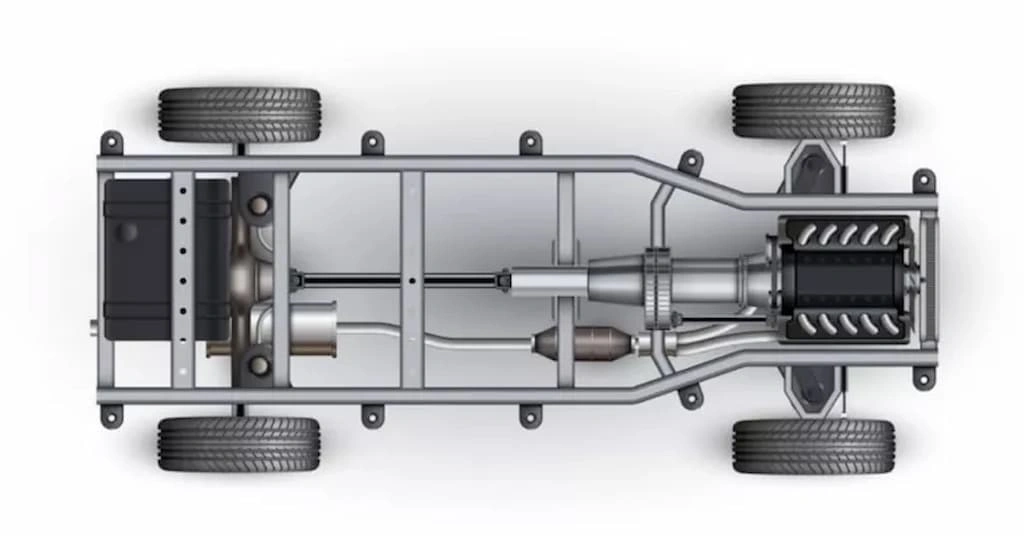

In the automotive sector, it is used for cutting exhaust pipes, chassis components, and structural frames, ensuring high accuracy and repeatability in mass production.

The construction industry leverages this machine for fabricating steel beams, railings, and support pipes, where clean cuts and tight tolerances are critical for safety and assembly.

Additionally, in furniture manufacturing, it enables the production of metal parts for tables, chairs, and decorative elements, offering versatility in design and material handling.

The aerospace field benefits from its ability to process lightweight alloys for aircraft tubing, maintaining strict quality standards.

Moreover, general metal fabrication workshops utilize this equipment for custom projects, reducing lead times and enhancing overall operational efficiency. Its adaptability to various materials and sizes makes it a cornerstone in modern industrial applications, driving innovation and cost-effectiveness.

Competitive Advantage: Why This Pneumatic Chuck Laser Pipe Cutter Outperforms the Competition

In the competitive landscape of industrial pipe cutting, selecting the right machinery is pivotal for profitability and efficiency. The Pneumatic Chuck Professional Laser Square Round Pipe Cutting Machine is not just another option; it represents a significant technological leap over conventional alternatives like manual saws, plasma cutters, and even older-generation mechanical chuck laser machines.

1. Superior Clamping Stability vs. Traditional Methods

The most immediate point of comparison is the clamping mechanism. Traditional manual saws rely on physical vices and clamps, which are time-consuming, inconsistent, and prone to human error, often leading to pipe slippage and material scrapping. Older laser cutters may use mechanical chucks that require manual adjustment. In contrast, the integrated pneumatic chuck system provides instantaneous, high-pressure clamping with the push of a button. This ensures the pipe is held with immense, uniform force throughout the cutting process, completely eliminating vibration-induced inaccuracies. This is a direct advantage over both manual methods and less automated laser cutters, resulting in a near-zero rejection rate for high-tolerance projects.

2. Unmatched Precision and Cut Quality vs. Plasma and Saw Cutting

When compared to thermal plasma cutting or abrasive saws, the laser cutting technology itself is the defining advantage. Plasma cutting generates a massive heat-affected zone (HAZ), warping thin-walled pipes and leaving behind dross that requires secondary finishing work. Saw cutting produces burrs, chips, and dimensional inaccuracies. Our laser pipe cutter, however, utilizes a focused high-power laser beam that vaporizes material, yielding a clean, smooth, and burr-free cut edge with a minimal HAZ. This “cut-ready” finish eliminates the need for deburring or grinding, saving substantial post-processing labor and time, and directly translating to lower cost-per-part.

3. Integrated Automation and Operational Efficiency

The true value for **industrial fabricators** is measured in throughput and operational cost. This machine excels with its fully automated CNC control system. A manual saw operation is entirely dependent on skilled labor and is inherently slow. Even some basic laser cutters require significant manual intervention for programming and setup. Our machine, however, allows operators to upload complex cutting patterns (e.g., miters, holes, slots) directly to the CNC, which then executes the entire job with flawless repeatability. The pneumatic chuck works in tandem with the automation, drastically reducing non-productive “chuck time” between cuts. This seamless integration of clamping and cutting automation enables lights-out manufacturing capabilities, where the machine can run unsupervised for extended periods, maximizing asset utilization.

4. Versatility and Flexibility for Job Shops

For a job shop handling diverse orders, machine flexibility is a critical advantage. A dedicated saw might be set up for only round pipes, or a simple cutter may struggle with complex geometries. This pneumatic chuck laser cutter is inherently versatile. Its robust chuck design and advanced software can handle a wide range of shapes (square, rectangular, round) and sizes, from small-diameter pipes to large structural pipes, in various materials including mild steel, stainless steel, and aluminum. Switching between jobs is a matter of loading a new program and the raw material, making it ideal for both high-volume production and small, custom batches. This eliminates the need for multiple dedicated machines, saving floor space and capital investment.

5. Long-Term Durability and Lower Total Cost of Ownership (TCO)

While the initial investment in a professional laser pipe cutter may be higher than a plasma table or a saw, the Total Cost of Ownership (TCO) is significantly lower. The machine’s robust construction and the non-contact nature of laser cutting mean there is minimal wear and tear on consumable parts like saw blades. The precision reduces material waste to a bare minimum. Furthermore, the automation reduces labor costs and dependency on highly skilled operators. Over a 5-year period, the savings in labor, materials, and secondary processing operations often see the machine paying for itself, while manual or plasma systems continue to accrue high operational costs.

In conclusion, the Pneumatic Chuck Professional Laser Pipe Cutting Machine is not merely an incremental improvement but a holistic solution designed for the demands of contemporary manufacturing. It outperforms alternatives by merging the unparalleled accuracy of laser technology with the speed and reliability of pneumatic automation, offering **B2B industrial clients** a tangible competitive edge through reduced costs, enhanced quality, and superior production agility.

Free solution of pipe cutting machine!

Want to improve efficiency but still don’t know how to choose a pipe cutting machine? Click here to consult:

Related News

1. Prevention of Laser Condensation Laser cutting machinery requires water cooling for both laser and optical components. Given the high […]