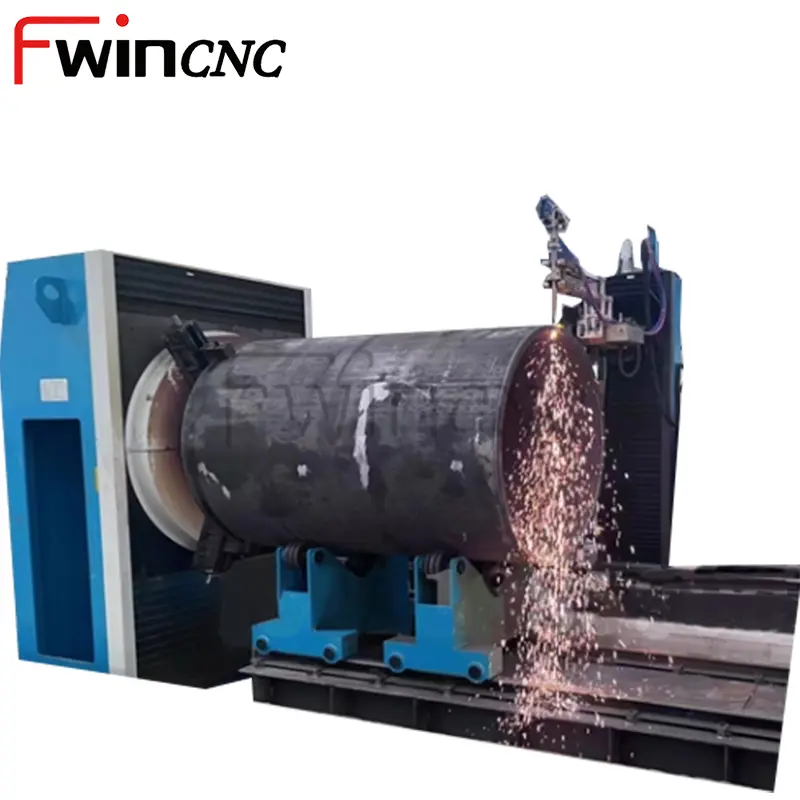

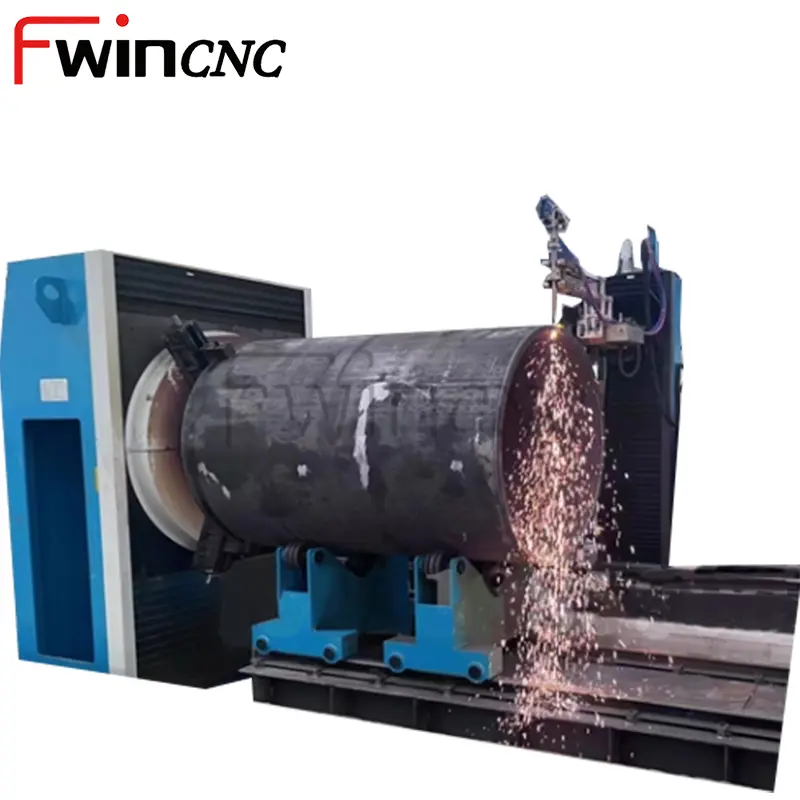

CNC plasma pipe cutting machine for round pipes up to 1000mm

Heavy-duty CNC plasma round pipe cutting machine up to 1000mm diameter, customizable length, high load capacity.

-

Designed exclusively for round pipe cutting, diameter up to 1000mm (customizable chuck)

-

Standard cutting capacity up to 400mm diameter, expandable configuration

-

Customizable pipe length up to 12 meters

-

Stepper motor drive supporting up to 1100kg pipe weight (customizable)

-

5 supporting legs for stable heavy pipe processing

-

Optional plasma and flame cutting combination

Heavy-Duty CNC Plasma Round Pipe Cutting Machine

The Heavy-Duty CNC Plasma Pipe Cutting Machine is engineered specifically for large-diameter round pipe processing. Designed for structural steel, offshore engineering, and heavy industrial fabrication, this machine provides stable, high-precision cutting for thick and oversized pipes.

With customizable diameter capacity up to 1000mm and pipe length extended to 12 meters, this CNC plasma pipe cutting machine is ideal for heavy-duty applications requiring strength, rigidity, and reliable performance.

This CNC round pipe cutting machine is purpose-built for processing heavy metal tubes. The standard configuration supports round pipes up to 400mm in diameter, while the chuck system can be customized to accommodate diameters reaching 1000mm.

Equipped with a reinforced frame and 5 supporting legs, the machine ensures stability when handling long and heavy pipes. The stepper motor transmission system supports loading capacities up to 1100kg, with customization available based on project requirements. This robust structure minimizes vibration during cutting, maintaining accuracy even with thick-walled pipes.

The cutting thickness depends on the selected plasma power supply, allowing flexible configuration based on material grade and processing demands. An optional flame cutting system can be integrated for processing thicker carbon steel pipes, expanding the machine’s capability beyond standard plasma cutting.

Designed for industrial-scale fabrication, this heavy-duty plasma pipe cutting machine improves operational efficiency, reduces manual handling risks, and ensures consistent cutting precision across long production cycles.

| No. | Model FW-ST400*12 | for heavy strong round pipe | |||

| 1 | metal pipe | diameter 50mm-400mm | |||

| 2 | Pipe length | 12000mm | |||

| 3 | Cutting Mode | Plasma | |||

| flame for option | |||||

| 4 | Rotary attachment | chuck diameter 320mm-1pcs | |||

| 5 pcs supporting legs | |||||

| 5 | Driving and motor | stepper motor to support 1100kgs loading pipe | |||

| 6 | loading capacity for pipe | customerized | |||

| 7 | lifting method | manual | |||

| Controller system | one set of startfire | ||||

| 8 | Height controller | startfire | |||

| rotation speed | 0.1-25r/min | ||||

| 9 | position accuracy | ±0.1mm | |||

| 10 | running accuracy | ±0.2mm | |||

| 11 | cutting speed | 0-6000mm/min | |||

| 12 | Torch height controller | Automatic THC | |||

| 13 | input power | 220±10%V AC50HZ/60HZ | |||

| 14 | tramsmission method | USB | |||

| Software | HiNest Technology pipe | ||||

| 15 | programe software | AutoCAD/CAM | |||

| 16 | Electrical components | CHINT | |||

Applications

This large-diameter plasma pipe cutting machine is widely used in:

-

Offshore and marine engineering

-

Oil and gas pipeline fabrication

-

Structural steel construction projects

-

Heavy equipment manufacturing

-

Bridge and infrastructure engineering

Its ability to process long and oversized round pipes makes it suitable for demanding heavy industry environments.

Large Diameter Customization Capability

Unlike standard plasma tube cutting systems, this machine is designed for oversized round pipes. The customizable chuck system and reinforced structure enable safe and accurate cutting of pipes up to 1000mm in diameter, meeting the demands of oil, gas, and infrastructure projects.

Flexible Plasma and Flame Cutting Integration

The optional plasma and flame dual cutting configuration increases versatility. Plasma cutting provides fast, precise cuts for medium thickness materials, while flame cutting supports thicker carbon steel pipes. This combination offers a comprehensive solution for heavy industrial pipe processing.

Cut Large Pipes With Precision

Upgrade your production capacity with a heavy-duty CNC plasma round pipe cutting machine built for oversized and thick-walled pipes. Designed for stability, strength, and flexible configuration, this system supports high-load processing while maintaining cutting accuracy.

Contact us today to receive customized diameter, length, and power configurations tailored to your industrial pipe cutting needs.