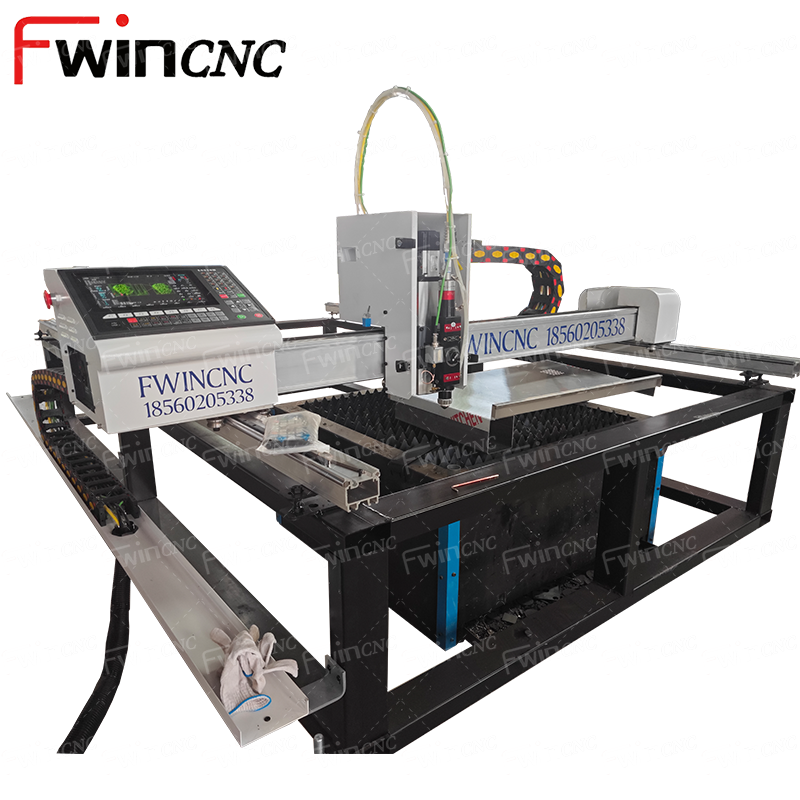

The Pipe cutting machine is a device that automatically calculates and cuts off the end of the steel pipe jojints, it does not require operator programming, only need to input the matched diameter of pipe, intersection angle parameters, the machine will automatically cut out the pipe intersecting lines and intersecting holes, it does not need manual polishing, widely used in the cutting and processing of pipeline structural parts in shipbuilding, construction, petrochemical, machinery, metallurgy and other industries. CNC pipe cutting machine is mainly composed of control system, arm system, drive device, clamping device, support device, guide rail, gas path system, control cabinet, operation table and other parts. Equipped with a plasma cutting system as the main cutting system.