Why Choose Air-Cooled Laser Welding

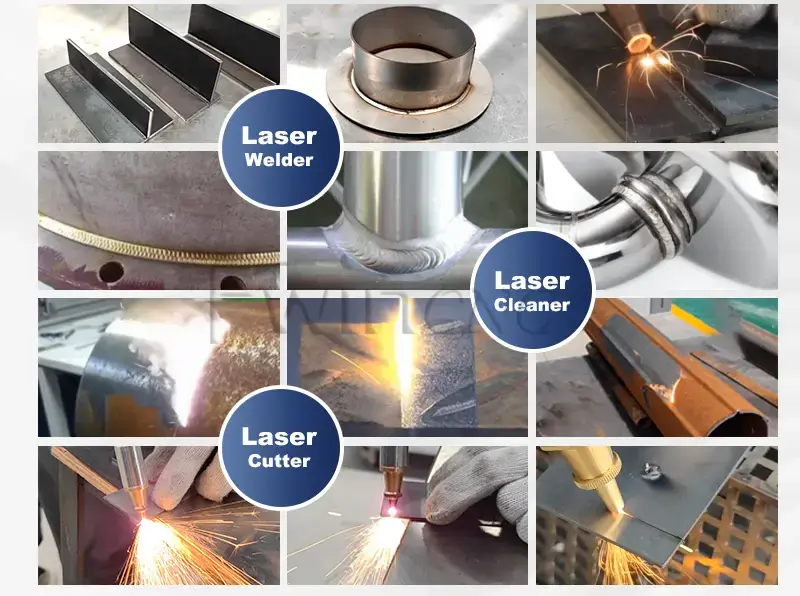

Choosing an air-cooled laser welding machine means prioritizing simplicity, mobility, and cost control. These machines are ideal for businesses that do not require continuous heavy-duty operation but still demand clean welds and stable performance.

For many users, air cooling provides sufficient thermal management while significantly reducing system complexity. This makes air-cooled laser welders a practical choice for workshops with limited space, regions with unstable water supply, or users seeking a more portable solution.

Air-Cooled vs Water-Cooled Laser Welding Machines

Water-cooled laser welding machines are typically designed for high-power, continuous industrial operation. They rely on external chillers to manage heat, which adds cost, space requirements, and maintenance responsibilities. While water-cooled systems are suitable for long-duration, high-load production, they may be excessive for lighter or intermittent welding tasks.

Air-cooled laser welding machines, on the other hand, use internal airflow systems to dissipate heat. This reduces setup time and eliminates the need for water management. Although air-cooled systems are generally limited to lower power ranges compared to water-cooled machines, they provide more than enough performance for many fabrication applications.

In short, water-cooled machines focus on maximum power and continuous output, while air-cooled models emphasize convenience, portability, and lower operating costs. The best choice depends on actual production needs rather than maximum specifications.